Drone Cleaning Solar Panels A How-To Guide

- James Baptiste

- Oct 7, 2025

- 13 min read

Updated: Oct 9, 2025

Using drones to clean solar panels is a huge leap forward for renewable energy maintenance. The whole idea revolves around using unmanned aerial vehicles (UAVs) outfitted with special cleaning gear to wash away dirt, dust, and grime from solar arrays, which in turn, boosts their energy output.

Why Drone Cleaning Is Redefining Solar Maintenance

It’s a simple fact: a solar panel’s efficiency is directly tied to how clean it is. Even a light dusting or a few bird droppings can cast a shadow, block sunlight, and seriously cut down on power generation. For a massive solar farm, this isn't just a minor annoyance—it can be a multi-million dollar problem that hits the return on investment hard.

Before we get into the drone side of things, it helps to understand the headaches that come with traditional solar panel cleaning methods. We're talking about crews working at dangerous heights, setting up tons of scaffolding, and using up a lot of water and time. All these logistical hurdles make regular, proactive cleaning a costly and difficult chore.

Overcoming Traditional Maintenance Hurdles

This is where drone cleaning solar panels really changes the game. Drones provide a solid solution to the biggest roadblocks in manual maintenance: safety, accessibility, and cost.

Enhanced Safety: Drones keep workers safely on the ground. This practically eliminates the risk of falls and other height-related accidents, which are always a major worry for rooftop jobs and large-scale solar farms.

Superior Accessibility: Drones have no trouble reaching panels on steep roofs, over rough terrain, or even on floating solar farms where getting traditional equipment is next to impossible.

Operational Efficiency: A single drone operator can often clean an area much faster than a whole crew, which means lower labor costs and less downtime for the facility.

This shift is all part of a bigger move toward automation in the renewables sector. The global solar panel cleaning market is on track to grow from USD 0.98 billion in 2024 to USD 1.93 billion by 2034, and that growth is fueled by this demand for smarter maintenance.

In dry, dusty regions where grime can slash energy output by as much as 25%, drones are an absolute necessity. They make it possible to keep everything running at peak performance without putting a strain on local water resources.

Drones transform solar panel maintenance from a reactive, labor-intensive task into a proactive, data-driven strategy. It’s not just about cleaning; it’s about optimizing asset performance with precision and safety.

At the end of the day, using drones isn't about replacing people. It's about giving them better, safer tools to do their jobs. It’s a strategic move that helps preserve the long-term health and productivity of our vital renewable energy assets.

Selecting Your Drone and Cleaning System

Picking the right gear for drone-based solar panel cleaning isn't as simple as grabbing a popular model off the shelf. Your success hinges on creating a perfectly matched system where the drone, its payload capacity, and the cleaning attachment work together seamlessly. Think of it less like buying a single tool and more like building a specialized toolkit for a very specific job.

The first big decision you'll face is the drone's airframe. The most common options are quadcopters (with four rotors) and hexacopters (with six). Quadcopters tend to be more agile and a bit easier on the wallet, making them a solid starting point.

But when you get into serious commercial work, a hexacopter is almost always the better bet. Why? It comes down to stability and redundancy. If a motor fails on a hexacopter, it can often still land safely—a non-negotiable feature when you're flying expensive equipment over thousands of dollars' worth of fragile solar panels.

Matching the Drone to the Job

Payload capacity is the number one spec you need to look at. This single number dictates everything. It doesn’t just determine if you can carry a cleaning system, but which system you can carry. A lightweight air blower for kicking up desert dust requires a lot less lifting power than a tethered system dragging a wet brush and a water hose.

You can break it down into a few tiers:

Light Duty (Payload < 5kg): This is the sweet spot for systems using high-velocity air blowers or electrostatic dusters. Perfect for jobs in arid climates where you're dealing with fine, loose dust.

Medium Duty (Payload 5-10kg): This range opens up your options to smaller soft-bristle brush systems or lightweight, low-pressure water sprayers. It’s a versatile category that can handle mixed conditions.

Heavy Duty (Payload > 10kg): Now you're in the big leagues. This is what you need for robust, tethered wet-cleaning systems that have to support the weight of a brush, motor, and a water supply hose. These are the workhorses for tackling stubborn grime.

While many drones are built for photography, you'll want an industrial-grade model. For a look at some powerful options, check out our guide on the top drones for industrial inspection in 2025 at https://www.jabdrone.com/post/top-12-drones-for-industrial-inspection-in-2025. Many of these have the tough builds and payload capacities you'll need.

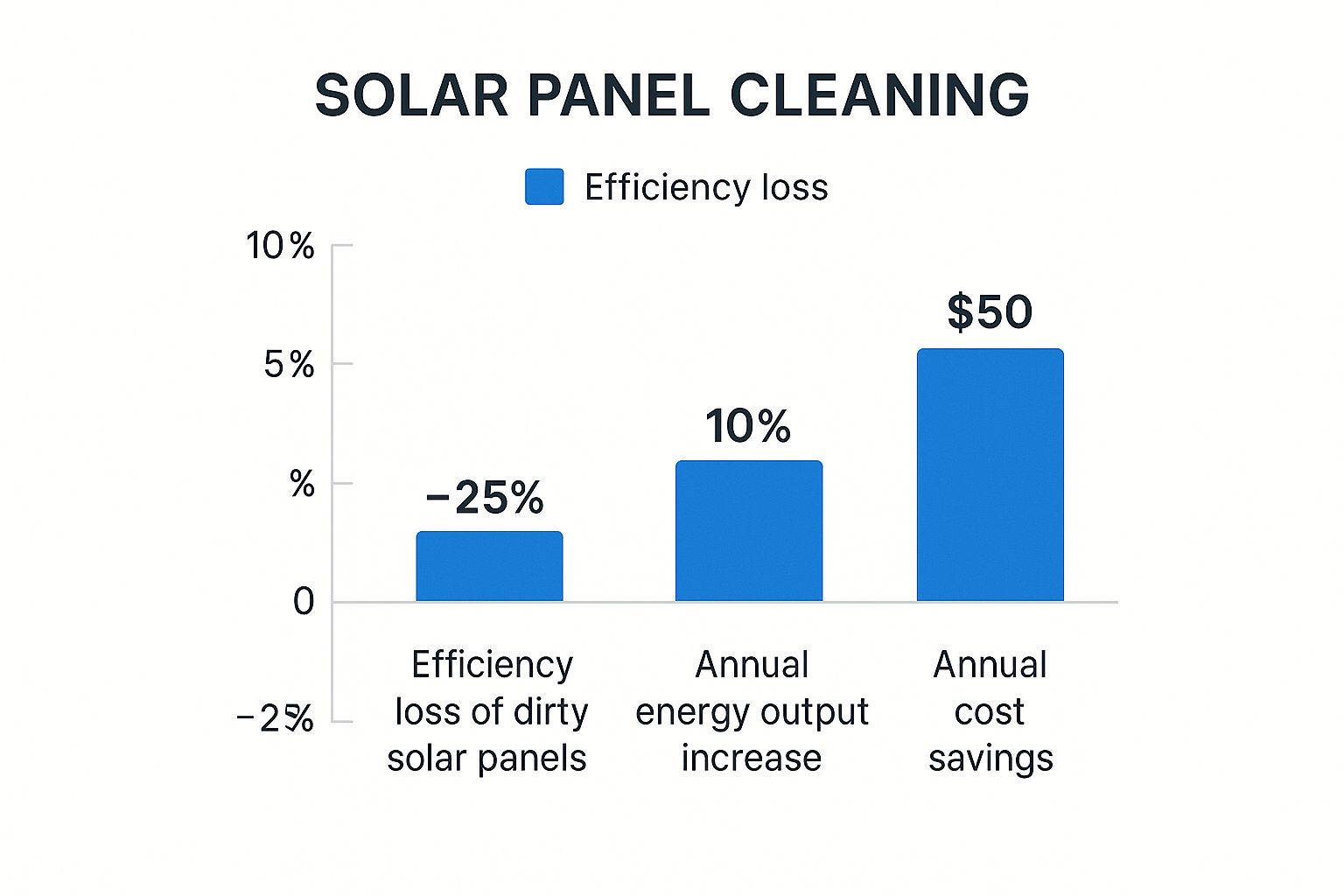

The infographic below really drives home the financial reason for getting this right. Keeping panels clean isn't just about appearances; it's about maximizing ROI.

As you can see, consistent cleaning directly translates to real energy gains and cost savings, making the investment in the right equipment a no-brainer.

Choosing Your Cleaning Method

Once you've zeroed in on a drone, it's time to pick the cleaning attachment. Just like any professional cleaning job, the right tool makes all the difference. This principle holds true across industries, and it's worth understanding the importance of specialized cleaning supplies to see the parallels.

For solar panels, there are a few primary methods, each with its own pros and cons.

Here's a quick comparison to help you decide which system aligns best with the kind of work you'll be doing.

Drone Cleaning System Comparison

Cleaning Method | Best For | Pros | Cons |

|---|---|---|---|

Soft-Bristle Brushes | Versatile cleaning for both light dust (dry) and stubborn grime (wet). | Highly effective on caked-on dirt, bird droppings, and pollen. | Requires a heavy-duty drone; tethered wet systems can be complex to manage. |

High-Velocity Air Blower | Arid and desert environments with loose sand and dust. | Waterless, fast, and eco-friendly. Very low operational cost. | Ineffective against wet or sticky residue. |

Low-Pressure Water Sprayer | General cleaning where a rinse is sufficient to remove dirt. | Safe for panels; uses deionized water to prevent mineral spots. | Requires a water source and careful management of the tethered hose. |

Ultimately, the best method depends entirely on your environment and the type of soiling you're up against. A farm in a dry, dusty area will have completely different needs than a coastal facility dealing with salt spray and bird droppings.

The Essential Pre-Flight Safety Checklist

When you're drone cleaning solar panels, success is built on the ground, long before you ever take off. This is one area where you absolutely cannot afford to rush. Skipping steps here is a fast track to disaster, putting expensive gear, the client's property, and your entire reputation on the line.

A solid pre-flight routine isn't just about ticking boxes for compliance. It's about maintaining absolute control and showing up like a pro.

Before the rotors even think about spinning, you need to get your boots on the ground for a site survey. Walk the entire operational area. You're looking for the kind of hazards that a satellite view will never show you.

Keep an eye out for things like:

Overhead power lines and low-hanging communication wires.

Tricky, uneven terrain or hidden obstacles that could trip you up while your focus is in the sky.

Nearby trees, buildings, or even radio towers that can mess with your GPS signal or create unpredictable wind tunnels.

Think of this walkthrough as your chance to build a mental map of the job site and spot problems before they have a chance to happen.

Physical Drone and Weather Inspection

Next up, you have to square off with the two most unpredictable elements of any job: your equipment and the weather.

Giving your drone a thorough physical inspection is completely non-negotiable. Get hands-on. Check the props for any nicks or stress cracks. Make sure every battery is fully charged and clicks securely into place. Double-check that your cleaning rig—whether it's a brush, blower, or sprayer—is attached firmly.

At the same time, you need to become a bit of a meteorologist. Wind is, without a doubt, your biggest enemy. Every commercial drone has a maximum wind resistance rating, and pushing that limit is just asking for a flyaway. A single strong gust can slam your drone right into a panel.

A safety-first culture is the most valuable asset for any drone services company. Cutting corners on pre-flight checks is a gamble that never pays off in the long run.

Don't just look at the current wind speed. You have to check the forecast for gusts throughout your entire planned flight window.

Finalizing Your Flight Plan

Okay, the site is clear and the gear is good to go. The last piece of the puzzle is locking in your flight plan. This means defining your exact flight path over the panels, setting up geofences to create no-fly zones around sensitive equipment, and reviewing your emergency procedures. What's the plan if you lose signal? What happens when you get a critical battery warning?

This is also the moment to confirm that you’re flying by the book. In the U.S., that means operating under FAA Part 107 rules for all commercial flights. For a more detailed breakdown of what this involves, our guide offers a deeper look into the core components of a drone pre-flight checklist that every pilot should master.

By making this checklist a non-negotiable part of every single job, you sidestep the common, costly mistakes that trip up other operators. It's how you guarantee every flight is as safe as it is effective.

Executing the Perfect Cleaning Flight

Alright, your gear is ready and you’ve run through all the pre-flight checks. Now for the main event. Actually flying the cleaning mission is a careful dance between speed, altitude, and precision. If you want a consistent, streak-free finish while getting the most out of every battery, you need to nail your flight patterns.

The two most common and effective patterns I see in the field are the 'serpentine' and the 'grid'. The one you choose really comes down to the layout of the solar array and the type of cleaning system you’ve got hooked up to your drone.

Choosing Your Flight Pattern

The serpentine pattern—sometimes called an S-pattern—is exactly what it sounds like. You fly the drone back and forth in continuous, overlapping lines across the panel rows. It’s incredibly efficient for those long, uninterrupted arrays you see on big solar farms because it minimizes sharp turns and saves precious battery life. This is my go-to for air blowers or sprayers where that continuous motion gives you the best coverage.

On the other hand, the grid pattern is a more methodical approach. You break the entire solar farm into smaller, manageable squares and clean one section completely before moving to the next. This is perfect for jobs that demand more precision, like when you're using a soft-bristle brush attachment that needs to make deliberate, even contact with the panel surface. It also makes it a lot easier to track your progress and make sure you haven't missed any spots, especially on funky, irregularly shaped installations.

The goal isn't just to fly over the panels; it's to execute a repeatable, systematic process that guarantees uniform results. Your flight pattern is the foundation of that consistency.

No matter which pattern you land on, one thing is non-negotiable: you have to maintain a consistent altitude and speed.

Mastering Altitude and Speed

Fly too high, and your cleaning tool—whether it’s pressurized air or a brush—loses its effectiveness. Fly too low, and you're just asking for a collision. I've found the sweet spot is usually between 1 to 3 meters above the panels, but always check your equipment manufacturer’s recommendations.

Speed is just as critical. A slow, steady pace ensures you’re cleaning thoroughly without leaving gaps. It’s tempting to rush the job to save a few minutes in the air, but I can tell you from experience it almost always leads to a shoddy clean. You’ll just end up having to do a second pass, which wastes way more time and battery in the long run.

For larger operations, this is where flight planning software becomes an absolute game-changer. Automating your flight path gives you a serious edge:

Unmatched Precision: The software executes the plan with centimeter-level accuracy. You get perfect overlaps and complete coverage, every single time.

Enhanced Safety: Automated flights let you plug in safety parameters like geofences and obstacle detection. This is a huge reason why a solid understanding of drone collision avoidance systems is a must for any professional operator.

Operational Scalability: You can save flight plans and use them again later. This turns even the most complex jobs into simple, repeatable workflows that any trained pilot on your team can execute flawlessly.

The demand for this level of maintenance is exploding. In 2023, the U.S. alone saw a staggering 51% increase in solar capacity installations, which has pushed the need for efficient cleaning solutions right to the forefront. Drones are stepping up, offering a safe, fast, and often waterless way to keep these massive investments running at peak performance. This blend of automated flight planning and skilled piloting is what really separates the amateurs from the pros.

Post-Flight Analysis and Equipment Care

The job isn't done just because the drone is back on the ground. What you do immediately after a cleaning flight is every bit as critical as your pre-flight inspection. This is your chance to confirm the quality of your work and perform the essential care that protects your gear and gets you ready for the next job.

First things first: review the flight data. Pull up the drone's camera footage—thermal, if you have it—and compare the before-and-after shots. You're hunting for any missed spots, streaks, or areas that might need another quick pass. It's also smart to cross-reference this visual review with your flight logs to see if a patchy clean corresponds to a weird dip in altitude or a sudden change in speed.

Think of this analysis as your own internal quality control. It’s how you dial in your flight patterns and techniques, turning a good clean into a great one, every single time.

Implementing a Routine Maintenance Schedule

Your drone system is a high-performance tool, and just like any other professional rig, it needs regular upkeep. Skipping out on maintenance is the quickest way to end up with equipment failure, expensive downtime, and flights that just aren't safe. All it takes is a simple, consistent checklist.

After every single flight, you need to:

Clean the Airframe and Components: Grab a soft, damp cloth and some compressed air to gently clear dust and grime from the drone's body, motors, and sensors. Pay close attention to the cleaning attachment itself—get any gunk out of the brushes or nozzles.

Inspect for Wear and Tear: Give the entire setup a good physical look-over. Check the propellers for any nicks or cracks. Even tiny damage can throw off your drone's stability. Examine the cleaning rig for loose connections and keep an eye out for stress marks on the drone’s frame or landing gear.

This quick daily check is your best defense against surprises on the job.

Long-Term Equipment Health

Beyond the daily wipe-down, your gear needs deeper maintenance every now and then to stay in top form. This includes keeping the firmware for the drone and controller up to date. Those updates often contain crucial security patches and performance boosts you don't want to miss.

Battery care is another huge piece of the puzzle. Always stick to the manufacturer’s instructions for charging, discharging, and storage. Leaving batteries fully charged or completely empty for long periods will seriously shorten their lifespan and reliability.

Proper equipment care isn't just about maintenance; it's about being operationally ready. A well-maintained drone is a reliable and safe drone, which means you can deliver professional results on every single job.

Keeping a detailed record of all this is non-negotiable. For a solid guide on what you should be tracking, check out our deep-dive article on why you need an essential drone maintenance log. That log becomes a complete history of your equipment, helping you spot recurring problems and plan for when you'll need to replace parts. This kind of systematic approach is how you maximize the life of your gear and keep your operation running like a well-oiled machine.

Got Questions About Drone Solar Panel Cleaning? We’ve Got Answers.

Jumping into drone-based solar panel cleaning is a big move, and it's totally normal to have a few questions rolling around your head. This tech is still a game-changer for a lot of asset managers, so let's cut through the noise and tackle the stuff we hear most often.

Think of this as a straight-to-the-point chat to give you the confidence you need.

Is Drone Cleaning Actually as Good as Doing It by Hand?

Honestly, for the typical dust and light grime that builds up on panels, drone cleaning is fantastic. It often matches, and sometimes even beats, the quality of manual work. Where it really shines, though, is in speed, safety, and consistency. A single drone can blitz through a huge solar farm in a tiny fraction of the time it would take a ground crew.

Plus, you're completely removing the human risk factor of working at height. No more boots on panels.

Now, if you're dealing with really stubborn, caked-on gunk or years of bird droppings, you might need a more aggressive solution. But for the regular, preventative cleaning that keeps a solar farm running at its best, drones are in a league of their own.

The real win with drone cleaning is being proactive. It lets you perform frequent, affordable maintenance that stops heavy soiling from ever becoming a problem in the first place.

This is how you protect your energy output and your bottom line over the long haul.

Is It Safe for the Panels Themselves?

One hundred percent—as long as it’s done by professionals with the right gear. These aren't just off-the-shelf drones. The systems are purpose-built for cleaning delicate photovoltaic surfaces. They use specialized, soft-bristle brushes and controlled, low-pressure sprays of deionized water.

This is all designed to clean thoroughly without leaving a single scratch or damaging the panel's anti-reflective coating. In many ways, it's safer than having people on the panels, where you can get inconsistent pressure or someone accidentally using the wrong tool.

What Are the Rules and Regulations for Flying a Cleaning Drone?

The legal stuff is a big deal and changes depending on where you are. Here in the United States, if you're flying a drone for any commercial purpose—and yes, cleaning solar panels counts—the pilot absolutely must have a Part 107 certificate from the FAA.

Beyond just the license, pilots have to stick to all the FAA rules of the sky:

Keep the drone within their visual line of sight at all times.

Never fly over people who aren't directly involved in the cleaning operation.

Know and respect all airspace restrictions, especially near airports.

Before you even think about launching a service, you have to do your homework and make sure you're fully compliant with every local, state, and federal regulation. No shortcuts here.

Can I Use a Drone to Clean My Rooftop Solar Panels at Home?

Technically, you could. But practically? It doesn't usually make much sense. The cost of the specialized equipment, the setup time, and dealing with all the regulations just doesn't pencil out for a small residential rooftop.

Drone cleaning delivers its best ROI on large-scale projects: commercial rooftops, industrial sites, and massive utility-scale solar farms. In those scenarios, manual cleaning is slow, dangerous, and incredibly expensive, making drones the obvious choice. For the average homeowner, a good old-fashioned manual clean is still the most practical way to go.

At JAB Drone, we live and breathe this stuff, and we're here to share what we know to help you succeed. Whether you're a seasoned pro or just getting your wings, check out our deep-dive guides and reviews at https://www.jabdrone.com to stay on top of your game.

Comments