Crop Dusting Drone: Boost Your Farming Efficiency Today

- Jab Media

- Oct 13, 2025

- 13 min read

Updated: Oct 15, 2025

A crop dusting drone is essentially an unmanned aerial vehicle (UAV) built specifically for agricultural spraying. These drones are taking the place of traditional methods like manned aircraft or ground-based sprayers, offering a whole new level of precision when applying fertilizers, pesticides, and other treatments to crops.

The New Era Of Farming From Above

Farming has always been a battle against the elements, from unpredictable weather to the ever-increasing cost of doing business. Today, a new tool is giving farmers a serious advantage in that fight. The crop dusting drone isn't just another piece of equipment; it's becoming a strategic partner in modern agriculture, fundamentally changing how we manage our fields.

To really get it, think of a traditional tractor-pulled sprayer as a broad paint roller. It's great for covering big, uniform areas, but it's not exactly precise. A crop dusting drone, on the other hand, is like an artist's airbrush. It delivers a fine, controlled spray exactly where it needs to go, cutting down on waste and making every drop count. This isn't a luxury anymore—it's essential for farming that's both sustainable and profitable.

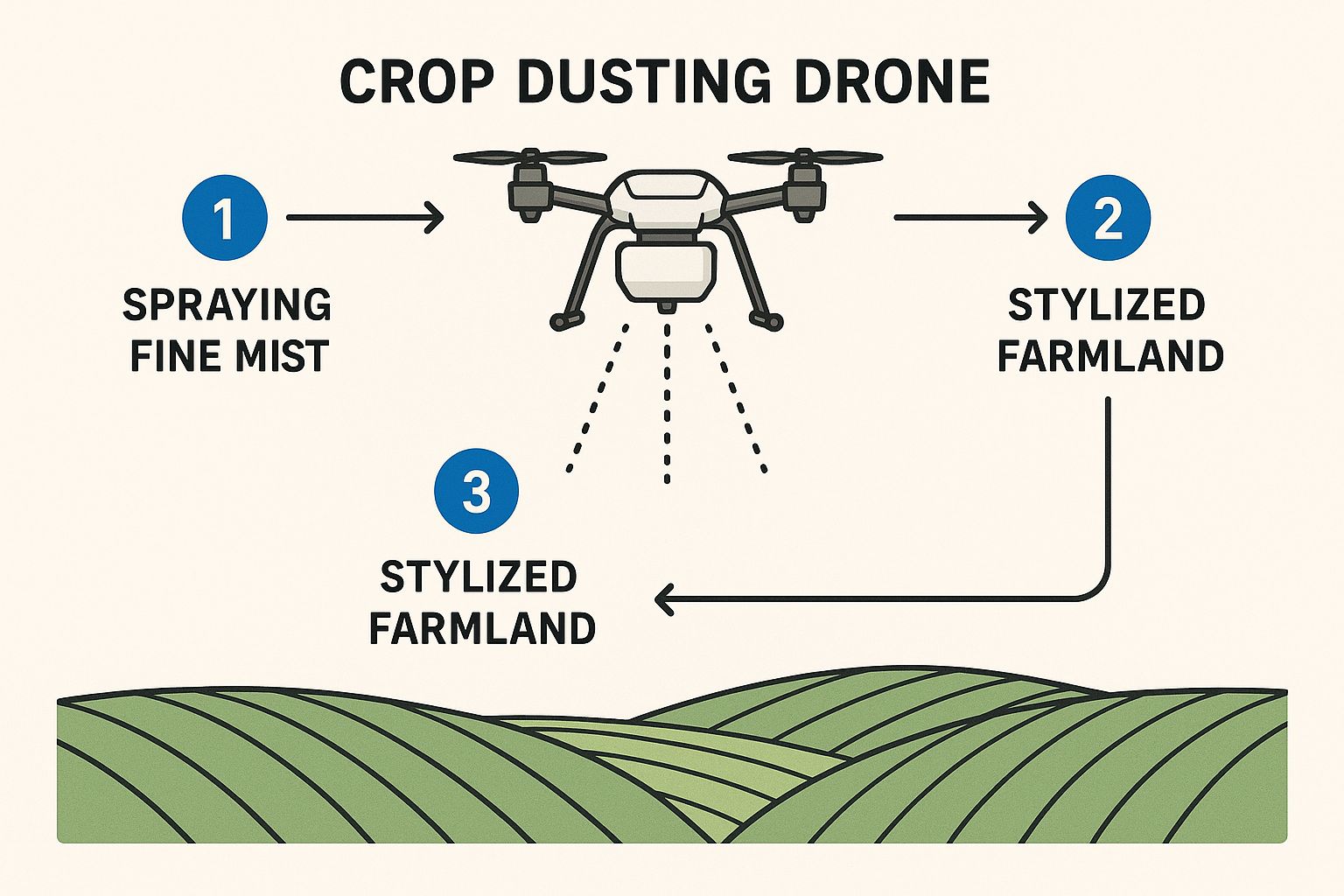

This infographic breaks down the streamlined process of using a crop dusting drone for a typical spraying mission.

As you can see, it’s a perfect blend of digital planning and autonomous execution, all geared toward getting better results in the field.

The Rise Of Precision Agriculture

The move toward drone technology isn't just a passing trend; it's a massive market shift. The global market for crop spraying drones was valued at around $1.39 billion in 2021. Projections show it rocketing to nearly $11.9 billion by 2028. That's a compound annual growth rate (CAGR) of about 35.8%, fueled by huge leaps in what these drones can do.

This rapid adoption is a direct response to some very real pressures farmers are facing:

Rising Input Costs: Fertilizers and pesticides aren't cheap. Applying them with precision means using less product to get the same, or even better, results.

Environmental Concerns: Targeted spraying drastically reduces chemical runoff into nearby water sources. It also minimizes the impact on beneficial insects and other non-target organisms.

Labor Shortages: Finding skilled labor is getting tougher. Autonomous drones can cover acres of land with minimal human supervision, filling a critical gap.

Soil Health: Heavy ground machinery compacts the soil over time, which hurts crop health. Drones fly above the fields, completely eliminating this problem and preserving the soil for future seasons.

By flying just feet above the canopy, a crop dusting drone ensures treatments are delivered directly to the plants, preventing the waste and environmental drift associated with traditional aerial application methods.

This technology is about more than just spraying, though. It's about gathering data to make smarter, more informed decisions. You can learn more about how drones are redefining modern agriculture in our detailed article. In the rest of this guide, we’ll dig into how these intelligent machines work, the real-world benefits they bring to the table, and what it takes to get them working on your own farm.

How Crop Dusting Drones Actually Work

A crop dusting drone looks complicated, but it's really just a smart system where tough hardware and intelligent software work together. It’s less like a single machine and more like a team, with each part playing a crucial role in delivering precise, automated crop care. At its heart, the drone is a purpose-built agricultural workhorse, blending raw power with surgical accuracy.

The physical drone itself is built to withstand the rigors of farm life. It all starts with a robust, often foldable frame designed to handle heavy payloads and the daily grind of fieldwork. This frame supports powerful, high-torque motors capable of lifting the drone, its batteries, and a full liquid tank, which can hold anywhere from 10 to over 50 liters depending on the model.

Attached to this powerful frame are specialized spray nozzles. These aren't your garden-variety sprinklers; they are advanced atomizing nozzles engineered to create perfectly sized droplets. This ensures the product coats plant leaves effectively without drifting away on the wind. It's this combination of components that creates a flying platform ready for any mission.

The Brains Behind The Flight

The real magic happens in the drone's sophisticated guidance and control systems. This is the "brain" that turns a simple remote-controlled aircraft into an autonomous farming tool. A few key technologies make this possible.

First is the flight controller, the central hub that processes commands and keeps the drone perfectly stable. It's constantly crunching data from a whole suite of sensors to manage altitude, speed, and orientation, allowing the drone to fly complex patterns without a human at the controls.

Next, a high-precision GPS (Global Positioning System) acts as the drone's navigator. But for this kind of work, standard GPS just isn't accurate enough.

That's where RTK (Real-Time Kinematic) technology comes in. RTK corrects GPS signal errors on the fly, achieving centimeter-level accuracy. This is what guarantees the drone sticks to its flight path, preventing missed spots or wasteful overlaps.

Finally, advanced sensors give the drone real-time awareness of its surroundings. An onboard radar system continuously scans the ground, letting the drone automatically adjust its height. This terrain-following ability is a game-changer for maintaining a consistent spray distance over uneven fields or rolling hills, ensuring every plant gets the same uniform coverage.

A Typical Mission From Planning To Execution

Running a spray mission is a clean, three-step process that goes from digital planning to automated fieldwork. Think of it as giving a robotic farmhand a digital map with a clear set of instructions.

Mission Planning: It all starts on a tablet or computer with specialized flight planning software. The operator simply draws a digital boundary around the field on a satellite map. Then, they input key parameters like the application rate, flight speed, and desired spray height.

Uploading and Pre-Flight Checks: With the plan set, it's uploaded wirelessly to the drone. The operator runs through a quick pre-flight checklist: batteries charged, tank filled with the right mix, and all systems go.

Autonomous Execution: With one tap, the drone takes off and gets to work. It flies the pre-planned grid entirely on its own, switching the sprayers on over the target area and off during turns. When the job is done or the tank is empty, it automatically returns to its takeoff point and lands.

This automated workflow lets the operator focus on monitoring the mission and mixing the next batch, making the whole operation incredibly efficient. That precision also has a huge impact on the farm's bottom line. To see how, check out our guide on the key factors influencing drone spraying cost per acre. This is the level of automation and accuracy that makes crop dusting drones such an essential tool in modern agriculture.

The Tangible Benefits for Your Farm

Sure, the tech is impressive, but what does a crop dusting drone actually do for your farm? The real value comes down to concrete results in your fields and on your balance sheet. Bringing a drone into your operation isn't just about looking modern; it's about making your farm more productive, profitable, and ready for whatever comes next.

These drones work smarter, not just harder. By taking to the sky, they neatly sidestep the limitations that have frustrated farmers for generations, turning old headaches into new opportunities.

Boosting Efficiency and Speed

One of the first things you'll notice is a huge jump in speed and flexibility. A crop dusting drone can get to work where heavy ground machinery simply can't. Think about those waterlogged fields after a heavy rain. A tractor would get bogged down, but a drone can fly right over, ensuring treatments happen on schedule.

That aerial advantage also solves another big problem: soil compaction. Year after year, heavy equipment squashes the soil, which hurts water absorption and root growth. Drones never touch the ground, leaving your soil structure intact for healthier crops.

Realizing Significant Cost Savings

Precision is money, and this is where a crop dusting drone really shines. Traditional sprayers, whether ground or aerial, almost always involve some degree of overspray. That’s just wasted money on expensive chemicals and water. Drones, guided by pinpoint navigation, apply treatments with near-surgical accuracy.

This targeted approach means you use only what you need, exactly where it’s needed. The financial impact is huge.

Reduced Chemical Use: You'll cut spending on pesticides, herbicides, and fertilizers by minimizing waste and drift.

Lower Water Consumption: Precise application rates mean you’re not wasting water to deliver treatments.

Decreased Fuel Costs: Drones run on electricity, completely eliminating the hefty fuel bills that come with tractors or manned aircraft.

For a deeper dive into how precision tools are changing the game, check out the benefits of agriculture GPS tracking.

Improving Crop Yields and Health

At the end of the day, it's all about a bigger, healthier harvest. A crop dusting drone gets you there by letting you respond to threats like fungal outbreaks or pest infestations with incredible speed.

Instead of a blanket, field-wide application, you can spot-treat problem areas before they have a chance to spread. This targeted response means healthier plants, less crop stress, and ultimately, better quality and higher yields.

By applying treatments directly onto the plant canopy, a drone ensures better coverage and absorption. This makes every application more effective and contributes to stronger, more robust plant health.

Achieving Sustainability Gains

The precision of a drone doesn't just help your wallet; it’s a big win for the environment. By drastically reducing chemical runoff, you're protecting the streams, rivers, and groundwater on and around your property.

This kind of responsible stewardship is more important than ever. The global impact is staggering—agricultural drones have already been used on over 500 million hectares of farmland worldwide. This has led to massive resource conservation, including saving an estimated 210 million metric tons of water and cutting pesticide use by nearly 47,000 metric tons. By adopting this technology, you're investing in the long-term health and sustainability of your land for generations to come.

Navigating Drone Regulations and Safety

Bringing a crop dusting drone to your farm is more than just unboxing new hardware. It’s about stepping into the world of aerial regulations. While that might sound intimidating, getting a handle on these rules is the key to operating both legally and safely, turning a potential headache into just another part of your workflow.

Think of it like getting a driver's license before taking a new tractor out on public roads. The sky has its own rules of the road, all designed to keep everyone safe.

For most places, this journey starts with pilot certification. Here in the United States, for instance, commercial drone operators must earn a Part 107 certificate from the Federal Aviation Administration (FAA). This certification proves you understand airspace rules, how weather affects flight, and general safe operating procedures. On top of that, the drone itself typically needs to be registered with the national aviation authority—giving it a unique ID number, almost like a license plate.

Core Operational Rules to Know

Once you’re certified and your drone is registered, you’ll need to follow a specific set of operational guidelines. These rules aren’t arbitrary; they’re there to prevent accidents and make sure everyone is flying responsibly. While the details can change from country to country, a few key principles are pretty much universal.

Most regulations require pilots to keep their drone within their visual line of sight (VLOS) at all times. You’ll also need to stick to altitude limits, which are usually around 400 feet above the ground, and make sure you’re not flying over people or moving cars. These are the foundational rules that form the bedrock of safe drone operations.

Of course, agriculture often demands more. For those massive fields that stretch as far as the eye can see, pilots may need to look into beyond-visual-line-of-sight (BVLOS) operations. You can learn more about the FAA's approach to these advanced flights in our detailed guide on FAA Part 108 explained for BVLOS operations.

Building a Strong Safety Culture on the Farm

Rules and regulations are only one piece of the puzzle. A true commitment to safety comes from building good habits and creating a culture of preparedness right on your farm. This practical side of things is just as crucial as any legal requirement.

It all starts with a pre-flight checklist. Develop one and use it every single time. This simple tool ensures you never miss a critical step, from checking battery levels and propeller integrity to making sure the spray tank is locked down tight.

A pre-flight checklist is your first line of defense against equipment failure. Spending just five minutes on a thorough check can prevent costly accidents and mission failures down the road.

Your safety plan also needs to account for the environment. Before every single flight, check the weather conditions. Pay close attention to wind speed and direction, which can have a huge impact on spray drift and the drone's stability.

Finally, have a simple emergency plan. What’s the procedure if the drone loses connection or has a malfunction? Knowing how to activate the "Return to Home" function and being comfortable with manual controls are essential skills. This also extends to the safe handling and storage of the chemicals you're spraying, ensuring they are managed responsibly from tank to field.

Choosing Your First Crop Dusting Drone

Stepping into the world of agricultural drones is a big move, and picking the right one from the start makes all the difference. You're not just buying a piece of equipment; you’re bringing a specialized robotic farmhand onto your team. The goal is to find a reliable partner that fits your farm's unique landscape, not just the drone with the biggest numbers on a spec sheet.

Think of this as an investment in a system that needs to slot perfectly into your daily workflow.

Key Factors to Consider

Before you even start looking at specific models, you need a crystal-clear picture of what you actually need it to do. The right drone for a 50-acre vineyard is going to be wildly different from one needed for 500 acres of corn.

Here are the core metrics you should be evaluating:

Tank Capacity: This is all about how much ground you can cover before you have to land and refill. Models can range from a nimble 10 liters for spot treatments up to 50 liters or more for serious, industrial-scale work.

Flight Time: This is your drone's stamina, tied directly to its battery life. More flight time means less downtime swapping out batteries and more acres sprayed per hour. It’s that simple.

Spray Width (Swath): A wider spray path means fewer passes to cover a field, which is a massive boost to your efficiency. The drone's size, nozzle setup, and how high it flies all play a part here.

Software Integration: How easy is the flight planning software to use? Can it import your field maps without a headache or sync up with the farm management systems you already use? Good software makes everything smoother.

For a deeper dive into picking the right model for your operation, check out our practical guide on [how to choose a drone](https://www.jabdrone.com/post/how-to-choose-a-drone-a-practical-guide).

The decision shouldn’t be driven by a single feature. A massive tank is useless without enough battery power to carry it effectively, and a wide spray swath is meaningless without the software to control it precisely.

Comparing Crop Dusting Drone Models

To give you a clearer picture, let's look at how different classes of drones stack up. Think of these as general tiers—the specific models and specs will vary, but this gives you a good starting point for what to expect at each level.

Feature | Entry-Level Model | Mid-Range Model | Professional Model |

|---|---|---|---|

Tank Capacity | 10-20 Liters | 20-40 Liters | 40-70+ Liters |

Typical Flight Time | 10-15 minutes (loaded) | 15-20 minutes (loaded) | 20-25+ minutes (loaded) |

Spray Width | 3-5 meters | 5-9 meters | 9-12+ meters |

Ideal For | Small farms, vineyards, spot treatments | Medium to large farms, diverse crops | Large-scale commercial operations |

Software Features | Basic flight planning, manual control | Advanced mapping, variable rate application | Full farm management integration, fleet control |

As you can see, the jump from entry-level to professional isn't just about size; it's about a complete system designed for higher efficiency and larger scale.

Understanding the Total Cost of Ownership

The price tag on the drone itself is just the beginning. A smart investment means looking at the total cost of ownership, which covers everything you'll need to keep your operation flying smoothly.

Your budget needs to account for these items:

The Drone Itself: The main piece of hardware.

Batteries and Chargers: You'll need a fleet of batteries—at least 4-6 per drone—and a powerful charging station to keep things moving with minimal downtime.

Software and Subscriptions: Some of the more advanced mapping features or data services might come with annual subscription fees.

Insurance: For any commercial drone work, liability insurance is non-negotiable. It protects your farm and your investment from accidents.

Maintenance and Repairs: Just like a tractor or a combine, your drone will need upkeep. Budget for replacing propellers, nozzles, and other parts that wear out over time.

This kind of forward-thinking financial planning is essential, especially in a market that's growing so quickly. Recent analysis shows the global crop spraying drone market is projected to expand from $2.47 billion in 2024 to $10.86 billion by 2029, a surge driven by the undeniable ROI of precision agriculture. You can [discover more insights about the growing crop spraying drone market on The Business Research Company](https://www.thebusinessresearchcompany.com/market-insights/crop-spraying-drones-market-insights-2025) to get a sense of where the industry is heading.

Of course. Here is the rewritten section, crafted to sound completely human-written and match the provided expert tone and style.

Common Questions About Agricultural Drones

When you're looking at a serious investment like a crop dusting drone, the spec sheets are one thing, but the practical, day-to-day questions are what really matter. Farmers want to know what this tech actually means for their operation. Let's get straight to the point and tackle some of the most common questions we hear.

How Many Acres Can a Drone Actually Cover in a Day?

This is probably the number one question, and the honest answer is: it depends. A drone’s daily coverage isn't a fixed number; it's a moving target based on how you run your operation.

A professional rig with a 40-liter tank and a 9-meter spray width can knock out 40-50 acres per hour. But that's just flight time. The real-world total comes down to your ground game.

Battery Management: A slick battery swapping and charging process is non-negotiable. If you have enough batteries and a solid charging station to create a continuous cycle, you can keep the drone in the air almost constantly.

Refill Logistics: How fast can you land, refill the tank, and get back up? A well-organized mixing and loading station right next to the field makes a world of difference.

Field Shape and Terrain: Flying long, straight passes over a perfect square is a lot faster than navigating an irregularly shaped field with trees or power lines that force constant turns.

When you factor all that in, a single, well-run drone team can realistically cover anywhere from 200 to 400 acres in a productive day.

Can You Really Spray in the Wind?

Wind is the eternal enemy of any aerial application, and drones are no different. Most spray drones have a hard limit, usually around 20-25 mph, where they simply won't fly safely. But the real magic is in how they handle moderate wind.

The downward thrust from the drone's propellers—what we call "prop wash"—is a game-changer. It actively pushes the spray down into the crop canopy, giving you a huge leg up against drift compared to traditional sprayers. It’s not a magic bullet, but it helps immensely.

The key to spraying in a breeze is all about control. By adjusting your droplet size, flying a bit lower and slower, and using the right nozzle tech, you can drastically minimize drift and make sure your product hits its target.

What Level of Training Is Actually Needed?

Flying a crop dusting drone is a lot more than just knowing how to use the joysticks. The official certifications, like the FAA's Part 107 and 137 in the US, are the legal baseline you have to meet. But real-world success comes from a much broader skill set.

You need to master the mission planning software, know how to properly calibrate your spray systems, and be comfortable with routine maintenance. You're part pilot, part mechanic, and part agronomist.

And for farmers with smaller operations, the question of ROI is everything. A crop dusting drone isn't just a tool for massive corporate farms. The savings on chemicals, the lack of soil compaction, and the sheer ability to treat spots you could never reach with a ground rig often deliver a quick and clear return on investment, no matter the size of your farm.

At JAB Drone, we're here to give you the expert insights and honest reviews you need to make the right call on your aerial tech. Explore our resources to stay ahead of the curve in the world of drones.

Comments