Top Drone Inspection Services: Complete Guide for 2024

- Paul Simmons

- Jun 18, 2025

- 15 min read

Understanding Drone Inspection Services and Their Impact

These services blend expert drone piloting with advanced data collection to provide clear, actionable information. This changes routine maintenance from a costly, high-risk task into a smart, proactive strategy.

More Than Just a Flying Camera

The real value of professional drone inspections comes from the specialized equipment they carry, which gathers information far beyond what the human eye can see. This isn't about taking pretty pictures; it's about collecting precise data that reveals the true condition of an asset. This is achieved with a variety of powerful tools.

High-Resolution RGB Cameras: These cameras capture visuals in such sharp detail that inspectors can spot tiny issues from a safe distance, like stress fractures on a bridge, corroded bolts on a cell tower, or a single damaged shingle on a massive commercial roof.

Thermal Imaging Sensors: Think of a thermal camera as a thermometer for infrastructure. It detects subtle differences in temperature that point to hidden problems, such as moisture trapped under a roof, an overheating electrical connection, or a malfunctioning solar panel.

LiDAR and 3D Modeling: LiDAR (Light Detection and Ranging) sensors use laser pulses to create incredibly accurate 3D maps of structures and landscapes. This information is used to build "digital twins," allowing for exact measurements and tracking of structural changes over time.

This combination of technologies is fueling major growth and interest. The global market for drone inspection and monitoring is expanding rapidly, driven by these technological improvements and a greater focus on safety. In 2024, the market was valued at an estimated $13.48 billion, with projections expecting it to reach $15.6 billion by the end of 2025. Discover the full market projections here.

The Regulatory Framework: Ensuring Safe and Professional Operations

The fast growth of drone inspection services is supported by clear regulations that draw a line between professional operators and recreational hobbyists. This structure is vital for ensuring safety, accountability, and reliability. In the United States, for example, the Federal Aviation Administration (FAA) provides a central resource hub for all unmanned aircraft systems (UAS) operators.

This official portal clarifies the distinction between flying for fun and flying for commercial purposes, laying out specific rules and safety guidelines for professionals. Qualified providers must follow strict requirements, including pilot certification (such as the FAA's Part 107 license), obtaining authorization for flights in controlled airspace, and carrying proper liability insurance.

These rules aren't just red tape; they are the foundation of a trustworthy service. This commitment to compliance guarantees that every operation is conducted safely and legally, protecting the client, the public, and the property being inspected. This established professionalism is a major reason why industries are now confidently using drones for essential maintenance and safety work.

Industries Transformed by Professional Drone Inspections

Professional drone inspections are no longer a niche technology; they are reshaping how entire industries operate. Imagine them not as a single tool, but as a multipurpose platform that can be adapted to solve very different problems. Whether it's scanning a vast energy grid or overseeing a chaotic construction site, drones offer a viewpoint that was once too expensive, dangerous, or simply impossible to get.

This new perspective is helping companies move away from fixing things after they break and toward preventing problems before they start, all thanks to better data.

Energy and Utilities: A Proactive Approach to Maintenance

The energy industry was one of the first to embrace drone technology, and it’s easy to see why. The job of maintaining huge networks of power lines, solar fields, and wind turbines is filled with logistical headaches and serious safety concerns. Drones serve as a forward scouting party, conducting detailed check-ups from a safe distance.

A drone equipped with a thermal camera can detect an overheating power line connection—something completely invisible to the human eye—long before it can cause a widespread blackout. A job like inspecting a 300-foot wind turbine blade, which used to require a team of rope specialists and a full day's work, can now be completed in less than an hour.

This shift toward preventative maintenance is attracting huge investment. The market for inspection drones is expected to jump from $5.96 billion in 2024 to an incredible $93.65 billion by 2037. This massive growth shows a deep change in how we care for our most important infrastructure. You can see the full market analysis on Research Nester.

Construction and Infrastructure: Building with Precision

A busy construction site can feel like a complex orchestra, and drone inspections give the site manager a conductor's podium. From the air, drones provide a real-time, bird's-eye view of the entire project, creating detailed aerial maps. This allows managers to check progress against the original plans and spot problems early.

Using technology like LiDAR, drones can measure the volume of material stockpiles with amazing precision, helping to avoid expensive ordering mistakes that lead to delays. The same logic applies to public infrastructure. Instead of shutting down a bridge to inspect its underside with cranes, a drone can fly underneath to find stress fractures or rust, catching issues years before they pose a risk to public safety. This information is used to build a "digital twin"—a precise 3D model that tracks the asset's condition over its entire life.

While the applications are varied, each industry uses drone technology to solve its own unique set of problems. The table below offers a closer look at how different sectors are using these aerial tools to achieve real-world results.

Drone Inspection Applications by Industry Comparison of how different industries utilize drone inspection services, including typical applications, benefits, and frequency of use

Industry | Primary Applications | Key Benefits | Inspection Frequency |

|---|---|---|---|

Energy & Utilities | Wind Turbine Blades, Solar Panels, Power Lines, Substations | Predictive Maintenance, Enhanced Safety, Reduced Downtime | Quarterly to Annually |

Construction & Infrastructure | Site Monitoring, Stockpile Measurement, Bridge & Building Checks | Progress Tracking, Cost Savings, Digital Twin Creation | Daily to Monthly |

Telecommunications | Cell Tower Audits, Antenna & Cable Checks, Structural Integrity | Worker Safety, Speed, Reduced Tower Downtime | Annually or As-Needed |

Agriculture | Crop Health Analysis, Irrigation Mapping, Pest Detection | Increased Yields, Resource Savings, Targeted Treatments | Weekly to Seasonally |

As the table shows, the core advantages—improved safety, faster inspections, and more accurate data—are found across the board, even when the specific tasks are very different.

Telecommunications and Agriculture: Reaching New Heights and Fields

The main challenge in the telecommunications world has always been working at great heights. Traditionally, inspecting a cell tower meant a technician had to make a dangerous climb. Professional drone inspections have made this risky task nearly obsolete. A drone can fly around a tower, taking clear photos of antennas, cables, and the structure itself, while the technician safely reviews the footage from the ground.

This method is drastically safer and significantly faster, which means less tower downtime and fewer service interruptions. In agriculture, drones are becoming a farmer's best friend. They can fly over huge fields to collect information on crop health, pinpointing spots that have pest problems or need better irrigation. This allows farmers to apply treatments only where they are needed, saving money and improving their harvest. Learn more about these techniques in our guide to drones in agriculture.

Why Smart Businesses Choose Drone Inspection Services

The Bottom-Line Benefits: Cost and Speed

Let's talk money, because the numbers are hard to ignore. Companies regularly see cost reductions between 30-50% compared to older methods. For instance, a bridge inspection that might cost $10,000 with a manual crew can often be completed for half that with a drone. These savings come from not needing to rent expensive gear like cranes, cutting down on crew hours, and preventing long, costly shutdowns.

It's not just about the money, but also the time. An inspection that used to tie up an asset for days or weeks can now be finished in a matter of hours. A drone can check a massive wind turbine in less than an hour, a job that would take a specialized rope access team a full day. This speed gets your equipment back to work faster, keeps projects on track, and allows your team to address problems right away.

From Raw Data to Strategic Insight

Drones provide a much higher quality of information. Their high-resolution cameras can spot tiny details like hairline cracks or a single rusted bolt that a person might miss from a distance. Thermal sensors can see what the human eye can't, like hidden moisture buildup or electrical parts that are about to fail.

This detailed, unbiased information takes the guesswork out of inspections. It gives engineers a clear, provable record of an asset's health, leading to more accurate and reliable assessments.

Gaining a Competitive Advantage

This better information is what allows businesses to move from fixing problems after they happen to preventing them in the first place. This is known as predictive maintenance. By analyzing data from regular drone flights, you can spot trends and predict when a part will need service, potentially saving a fortune by avoiding unexpected breakdowns.

A complete digital record of inspections also strengthens your case with insurance providers and demonstrates that you are meeting regulatory requirements. It's simply a smarter way to manage your operations.

To see the difference clearly, let's compare the old way of doing things with the new drone-based approach. This table breaks down the key factors.

Traditional vs. Drone Inspection Methods

Direct comparison of costs, safety, time requirements, and data quality between conventional inspection methods and drone-based alternatives

Inspection Method | Average Cost | Safety Risk Level | Time Required | Data Quality |

|---|---|---|---|---|

Traditional (Manual) | High (Labor, Equipment, Downtime) | High (Working at Heights, Confined Spaces) | Days to Weeks | Subjective, Inconsistent |

Drone Inspection | Moderate (Reduced Labor & Equipment) | Low (Remote Operation) | Hours to Days | Objective, Comprehensive, Verifiable |

As the table shows, drones offer a clear advantage in safety, speed, and data quality while often reducing overall costs.

In the end, choosing drone inspection services is more than just an operational update—it’s a competitive one. By cutting costs, shortening project timelines, and supplying the data needed for predictive maintenance, drones help companies become more resilient and profitable. The detailed visual reports set a new benchmark for managing assets, providing a level of understanding that was impossible before. Companies that stick to the old ways risk being left behind by those who have adopted this safer, faster, and more economical method.

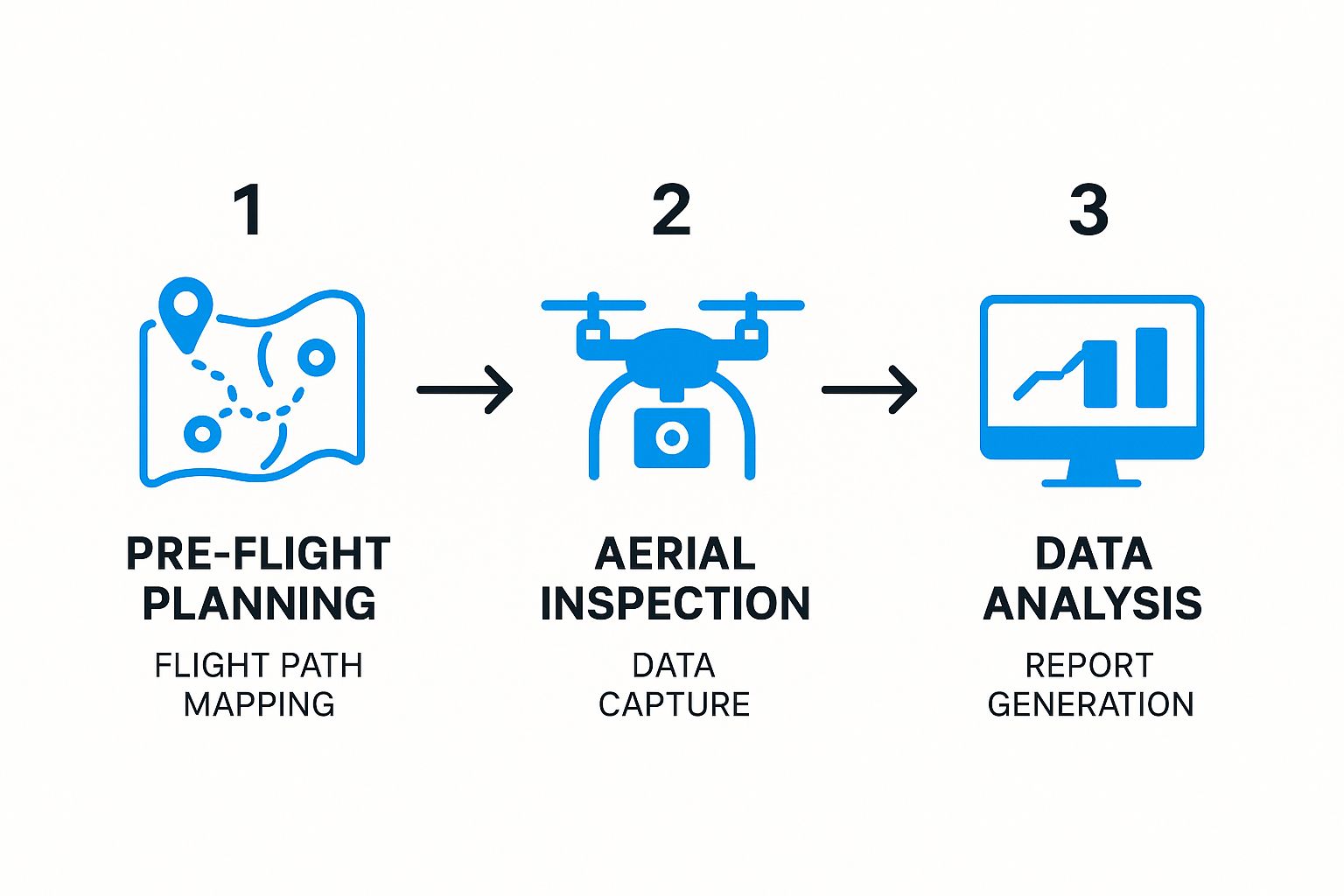

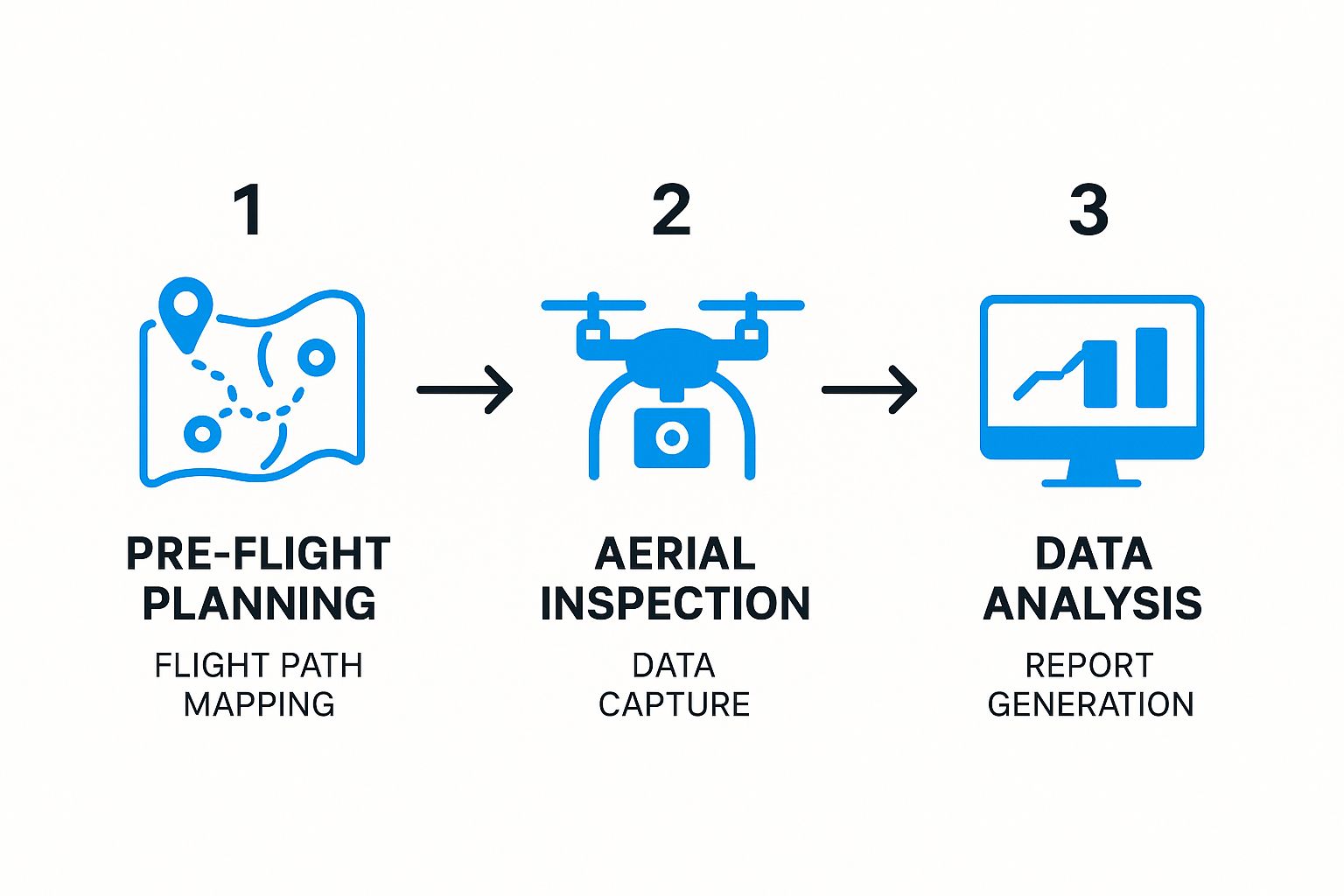

Inside Professional Drone Operations: Process Revealed

What separates a hobbyist's flight from a professional mission? It all comes down to a repeatable and meticulous process. A professional drone inspection services operation is a carefully managed project from start to finish. The goal is to ensure every flight delivers clear, reliable data that a business can act on with confidence.

The Pre-Flight Blueprint: More Than Just a Checklist

A successful inspection is determined long before the drone's rotors start spinning. This pre-flight planning stage is like an architect drawing up a detailed blueprint; it sets the foundation for the entire project. Skilled operators think through every variable to guarantee a safe and productive mission.

This careful preparation involves several key steps:

Defining the Mission: What are we looking for? Are they tiny stress fractures on a bridge or heat loss from a roof? The objective dictates the type of data needed.

Scoping Out the Site: This includes checking weather forecasts, identifying ground-level obstacles like trees or power lines, and studying the asset's structural plans.

Clearing the Airspace: Professionals check all airspace restrictions to ensure full compliance with FAA regulations and local ordinances, making certain the flight is completely legal.

Plotting the Course: Operators design automated flight paths, programming the drone to ensure it covers every inch of the inspection area. This also allows for perfectly identical flights in the future to track changes over time.

This planning isn't just about avoiding issues; it's about making sure the data collected is precisely what the client needs to make informed decisions.

In-Flight Operations: Executing with Precision

With a solid plan in place, the flight operation can begin. This stage is a blend of automated accuracy and human oversight. A certified commercial drone pilot is always in command, acting as a mission director rather than just a remote-control operator. While the drone executes its pre-programmed flight path, the pilot monitors its systems, the live data feed, and the surrounding environment.

This approach ensures the drone keeps the perfect distance and angle to capture consistent, high-resolution data. The drone is often equipped with special sensors, like thermal cameras to spot temperature differences or LiDAR scanners to build detailed 3D models. These tools gather information that is invisible to the human eye, providing a deeper level of insight. This methodical approach to data capture is the heart of effective drone inspection services.

The visual below shows how this professional workflow breaks down into three core stages: planning, flying, and analyzing.

This systematic process shows how professional drone inspection services turn raw aerial data into a valuable business report, with each step building on the last.

Post-Flight Analysis: Turning Data into Decisions

The mission isn't finished when the drone lands. The initial output—which could be thousands of images or huge 3D data files—is just the raw material. The post-flight analysis phase is where this information is transformed into real intelligence.

Specialized software is used to stitch images together into a single map, create dimensionally accurate 3D models, and process the sensor data. This is often assisted by AI algorithms that can scan the visuals to automatically detect and flag potential issues like cracks, rust, or heat anomalies.

This mix of powerful software and expert human review uncovers defects with a high degree of accuracy. The final result is a detailed, easy-to-read report that pinpoints problem areas, offers clear visual proof, and gives actionable recommendations. This is where the true value of the service is delivered, giving clients the insights they need to make smart maintenance decisions.

Navigating Drone Regulations and Compliance Requirements

These rules protect your business, the public, and the drone inspection services industry as a whole. Understanding this legal landscape is what separates a legitimate, professional operator from one that could expose you to major liabilities.

The FAA's Part 107 Rule: The Foundation

In the United States, the cornerstone of commercial drone operations is the Federal Aviation Administration's (FAA) Part 107 rule. This isn't just a guideline; it's the official commercial license for drone pilots. Any operator flying for business purposes, whether for photography or a complex industrial inspection, must hold a Remote Pilot Certificate.

To get this certificate, a pilot must pass a demanding knowledge test that covers airspace classifications, weather patterns, and emergency protocols. It’s the minimum qualification ensuring the person flying a drone over your asset knows how to do it safely and legally. The FAA provides all the necessary information for commercial operators on its official UAS website.

Insurance and Other Layers of Compliance

While Part 107 is the national standard, a professional drone provider must deal with more. Full compliance means managing several layers of rules, which often include:

Local Airspace Restrictions: Flights are often restricted near sensitive locations like airports or government buildings. A professional uses specialized tools to obtain authorization to fly in this controlled airspace.

State and Municipal Laws: Some cities or states have their own drone regulations, which frequently address privacy concerns or local hazards.

Industry-Specific Requirements: Certain sectors, such as energy or telecommunications, may have additional safety or data security standards that a provider must follow.

One of the most important layers of protection is comprehensive liability insurance. A reputable drone inspection services provider will carry substantial coverage, often $1 million or more, to protect your business from any costs related to an accident. This is a key detail that shields you from serious financial risk.

Another rule is Remote ID, which works like a digital license plate for the drone by broadcasting its identification and location. This improves accountability and public safety. If you want to learn more about this specific rule, you can check out our guide on drone Remote ID compliance.

Ultimately, choosing a provider who is serious about compliance is about managing your own risk. An operator who invests in being fully licensed, insured, and aware of all regulations shows a true commitment to safety and professionalism. It proves they understand that a successful inspection is one that is not only effective but also free of legal and financial headaches. Asking for proof of certifications and insurance is a critical step in your hiring process. It makes sure your investment in drone inspection services is both smart and secure.

Industrial Applications Where Drones Excel Most

Heavy industries, from manufacturing to energy, operate in high-stakes environments where a single equipment failure can have massive consequences. Drone inspection services are giving leaders in these fields a new tool, offering a safe, bird's-eye view that brings a fresh level of clarity and foresight to complex operations.

Seeing Problems Before They Happen with Thermal Imaging

Imagine being able to spot a critical equipment failure days before it happens. That’s the real power of thermal imaging. In a refinery or on a factory floor, overheating machinery is a huge red flag, but it's often a problem you can't see with your own eyes. A drone carrying a thermal camera acts as an early warning system, flying over vast areas of pipes, motors, and electrical cabinets to pinpoint temperature anomalies.

This changes maintenance from a reactive scramble to a proactive strategy. Instead of dealing with the fallout of an emergency shutdown, which can cost millions in lost production, a company can identify a "hot spot" on a thermal scan and schedule a fix during planned downtime. This is a game-changer for:

Electrical Substations: Finding faulty connections or overloaded circuits before they cause a fire or blackout.

Manufacturing Plants: Monitoring heavy machinery for signs of friction or an impending electrical malfunction.

Chemical Processing: Ensuring reactors and pipelines are operating within safe temperature ranges.

Accessing the Inaccessible: Confined Space Inspections

Many industrial sites have confined spaces—such as storage tanks, boilers, and pressure vessels—that are incredibly dangerous and difficult for humans to inspect. Traditionally, this process required complex safety setups, including ventilation, scaffolding, and standby rescue teams, leading to significant costs and long asset downtimes.

Specialized drones designed for confined spaces are changing the game. These small, often caged, drones can fly into these hazardous areas while the operator remains safely outside. They capture high-resolution images of internal welds, corrosion, and structural integrity without a single person ever needing to enter. This not only dramatically reduces risk but also cuts inspection time from days to mere hours, getting critical equipment back online much faster.

The Financial Case for Industrial Drone Adoption

The clear improvements in safety and efficiency are driving serious investment. The numbers tell a story of rapid adoption, with the industrial drone inspection market projected to grow from $746 million in 2024 to an astonishing $4,621 million by 2035. This is a nearly five-fold increase in just over a decade, signaling a deep industry commitment. Discover more about these market growth projections.

This growth is fueled by proven results in sectors like power generation, where maintaining a sprawling network of power lines and towers is a massive logistical challenge. Drones now perform these inspections without requiring linemen to climb dangerous structures or needing expensive helicopter flights. The data collected helps utilities prevent outages and better manage their infrastructure. You can explore a detailed breakdown of how this technology is applied in our article about safe and cost-effective powerline inspection with UAVs. By using drone data for predictive maintenance, industrial firms are not just preventing failures; they are actively building more resilient, efficient, and profitable operations.

Choosing the Right Provider for Your Needs

Think of hiring a drone inspection services provider like you would a medical specialist. You wouldn't see a general doctor for heart surgery. The drone itself is just a tool, like a stethoscope. The real value comes from the pilot's expertise and their ability to analyze the data they collect.

It can be tempting to go with the lowest bidder, but a poor-quality inspection can lead to much bigger, more expensive problems later on. You’re not just buying flight time; you’re investing in the health of your asset.

Beyond the Basics: Vetting Technical Capabilities

First, look past the drone to its payload—the specialized sensors it carries. A professional provider will use the right tool for the job. For instance, a standard camera won’t find moisture trapped under a roof, but a thermal sensor will. Ask any potential provider to explain their equipment choice for your specific project. This ensures they are focused on your goals, not just using what they happen to have.

What happens after the flight is just as important. The best drone inspection services don’t just hand you a folder of raw images. That's a huge red flag. Instead, you should expect a detailed report that highlights specific problems, includes helpful notes, and provides clear recommendations. This report is the actual product you are buying, so be sure to ask for and review samples.

Industry-Specific Experience Matters

A pilot who has inspected 100 cell towers knows exactly where to look for common points of failure, an insight a generalist pilot won't have. Industry-specific experience isn't a bonus; it's a fundamental requirement. A provider who knows your industry understands its unique challenges, safety rules, and what data actually matters. This guarantees the final report gives you useful, practical insights.

This kind of expertise goes far beyond the basic FAA Part 107 certification, which is only the minimum legal standard for commercial drone work. Top-tier pilots receive hands-on training for inspecting specific assets like wind turbines or bridges. To get a better idea of the foundational skills involved, you can learn more in our article about how to become a commercial drone pilot. Always ask for case studies relevant to your industry.

To help guide your conversation, use this simple checklist when you interview potential drone inspection services providers. How they answer will tell you a lot about their level of professionalism.

Essential Questions for Your Drone Provider

Category | Key Question |

|---|---|

Compliance | Can we see your FAA license and insurance certificate? |

Experience | Can you show us examples from our industry? |

Technology | What sensors and software will you use for our project? |

Data Security | How will you protect our inspection data? |

The Critical Safety Net: Insurance and Security

Never overlook the legal and financial safeguards. Liability insurance is non-negotiable. A professional provider will carry a significant policy, with $1 million in coverage being a common industry standard. Always ask for a Certificate of Insurance (COI) that names your company as an "additionally insured." This is your official proof of protection if an accident happens on your property.

Data security is equally vital, especially when inspecting critical infrastructure. You are sharing sensitive information about your asset's weak points with a third party. Ask direct questions about how they manage your data: Where is it stored? Who can access it? Is it encrypted? A professional firm will have clear, confident answers that show they are committed to protecting your information.

Ultimately, the right provider delivers actionable intelligence, not just pretty aerial photos. To stay current with expert insights and the latest in drone technology, explore the complete resources available at JAB Drone.

Comments