Powerline Inspection UAV: Safe, Cost-Effective Utility Solutions

- A.E. Williams

- May 5, 2025

- 10 min read

The Evolution of Powerline Inspection UAV Technology

Powerline inspections have changed drastically. Previously, manual inspections were the standard, often requiring dangerous climbs and costly helicopter surveys. This resulted in slow progress, significant expenses, and inherent safety concerns for inspection crews.

However, the introduction of Unmanned Aerial Vehicles (UAVs), or drones, has significantly altered this process. These remotely piloted aircraft provide a safer, more efficient, and more affordable method for monitoring and maintaining essential power infrastructure.

This change wasn't immediate. Early powerline inspection UAVs were simple platforms equipped with basic cameras, mainly used for visual checks. While they offered an aerial perspective, their functionality was restricted.

This meant that many minor defects could be overlooked. But advancements in sensor technology rapidly expanded the capabilities of these UAVs beyond basic visual inspections.

From Visuals to Multi-Sensor Platforms

The addition of high-definition cameras, thermal imaging, and LiDAR systems has dramatically improved the detail and amount of data collected during inspections. High-definition cameras capture precise images of conductors and insulators, allowing inspectors to spot even small cracks or corrosion.

Thermal imaging detects overheating components, pinpointing potential problems before they cause outages. This allows for targeted and prompt preventative maintenance, minimizing downtime. LiDAR creates detailed 3D models of the powerline network. This helps with vegetation management and identifying encroachment problems that might affect service.

The Impact of Advanced Sensor Technology

The combined data from these sensors enables more precise and timely assessments. The change has been significant. Traditional helicopter inspections cost $3,000-$5,000 per hour. Modern drones achieve similar coverage with an 80-90% cost reduction and eliminate risks to personnel.

Thermal imaging and LiDAR-equipped UAVs now identify issues such as overheating conductors and vegetation encroachment with centimeter-level accuracy. Explore this topic further. This enhanced accuracy facilitates targeted maintenance and repairs, optimizing resource use and lowering operating costs. These developments improve powerline inspection, allowing utilities to provide consistent service while minimizing expenses and hazards.

The Economic Impact of Powerline Inspection UAVs

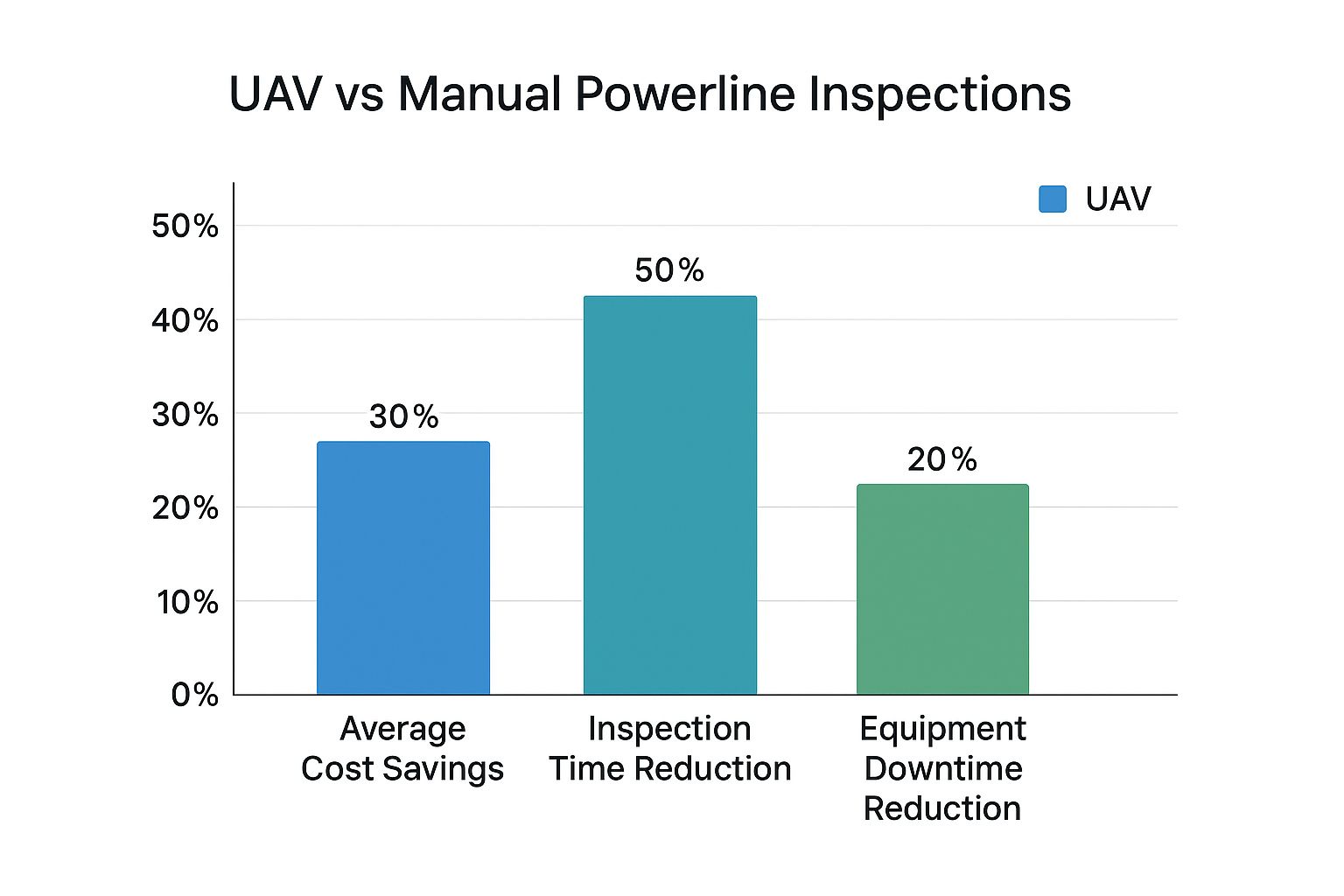

Powerline inspection using UAVs (Unmanned Aerial Vehicles) offers significant economic advantages. These benefits go beyond simply reducing labor costs. Preventative maintenance, facilitated by drone inspections, minimizes outages and their associated costs, directly improving a utility company's bottom line. The data chart above illustrates the cost and time savings associated with UAV inspections. It clearly shows how UAVs significantly outperform traditional methods in terms of cost-effectiveness and efficiency.

Return on Investment (ROI) With Powerline Inspection UAVs

Many companies are recognizing the substantial return on investment (ROI) from using UAVs. This ROI stems from multiple factors. First, drones reduce the need for expensive and time-consuming manual inspections, resulting in lower labor costs.

Second, improved inspection accuracy and frequency lead to more effective preventative maintenance. This ultimately minimizes costly repairs and losses due to power outages.

Finally, increased operational efficiency plays a vital role. UAVs can cover large areas rapidly, gathering high-quality data much faster than traditional methods. This efficiency translates into substantial cost savings.

The global drone power line inspection market reflects this trend. Growth projections are significant, ranging from $1.318 billion in 2025 to $15 billion by 2030, according to various analyses. One 2025 report even projected the market to reach $7.7 billion by 2033. Find more detailed statistics here. This growth is driven by energy companies modernizing their inspection processes, seeking greater grid reliability amidst rising energy demands.

Analyzing the Cost Advantages

Technological advancements have led to a rise in drone applications, including specialized systems for drone power line inspection. To understand the financial benefits, let's consider a cost comparison. The following table, "Cost Comparison: Traditional vs. UAV Powerline Inspection," presents a breakdown of operational costs, time efficiency, and safety metrics.

To illustrate these financial benefits, consider the following hypothetical comparison:

Inspection Method | Average Cost | Coverage Rate | Safety Risk | Defect Detection Rate |

|---|---|---|---|---|

Traditional (Helicopter/Manual) | $500 per mile | Lower | Higher | Moderate |

UAV-Based | $100 per mile | Higher | Lower | High |

This table summarizes the key advantages of UAV-based inspections. The 80% cost reduction per mile, coupled with faster coverage and improved safety, makes a compelling case for UAV adoption. The higher defect detection rate also contributes to enhanced grid reliability.

Regulatory Landscape and Investment

Evolving regulations surrounding UAV operations influence the economic outlook. While regulations can pose challenges, they also present opportunities for utility companies. Standardized certification procedures and operational guidelines provide clarity and foster safer drone integration into the airspace.

This regulatory development encourages investment in drone inspection programs. Utilities gain confidence in the long-term viability and legality of using UAV technology. You might be interested in: our sitemap for more information. As regulations continue to develop, it will be crucial for utilities to adapt and maximize the economic benefits of powerline inspection UAVs.

Industry Leaders Reshaping Powerline Inspection UAVs

The powerline inspection UAV sector is a dynamic and constantly evolving field. Key players are driving innovation and pushing the boundaries of what's possible in monitoring and maintaining critical energy infrastructure. These companies, both established giants and emerging startups, contribute significantly to the way we manage these vital assets.

Key Players and Their Contributions

Several companies stand out at the forefront of this technological advancement. For instance, Terra Drone is known for its comprehensive inspection services. They utilize high-end UAVs equipped with advanced sensors and data processing capabilities.

Flyability specializes in collision-tolerant drones. This technology allows for close-up inspections of complex structures, such as transmission towers, while minimizing risk.

Intertek, a global leader in quality assurance, also provides comprehensive inspection services using UAVs. This forms a key part of their broader asset integrity management solutions.

These industry leaders differentiate themselves through various strategic approaches. Some focus on developing proprietary sensor technologies for superior data acquisition and analysis.

Others prioritize AI-powered analytics platforms. These platforms enable automated defect detection and provide valuable insights for predictive maintenance. Another key area of differentiation is specialized hardware designed to withstand the demanding environments of powerline inspections.

Market concentration in this sector remains relatively high. In 2025, over 25 established players dominated the power line inspection drone sector. These top companies maintain their leading positions through substantial investments in research and development, particularly in areas like specialized sensors and AI-driven analytics. New companies are entering the market, though, and increased competition is anticipated. Learn more about market dynamics here.

Strategic Partnerships and End-to-End Solutions

Beyond the efforts of individual companies, strategic collaborations are playing a crucial role. Partnerships between drone manufacturers, sensor developers, and utility companies are becoming increasingly common.

These partnerships aim to create fully integrated solutions that address the real-world complexities of powerline inspections. This includes the challenges of inspecting dense urban networks and the demands of remote transmission lines.

This collaborative approach ensures that the technology meets the specific needs of end-users. It also effectively tackles the practical challenges of powerline inspection. By working together, these organizations accelerate the development and deployment of more effective and efficient solutions.

Overcoming Implementation Hurdles For UAV Programs

Implementing a successful powerline inspection UAV program involves more than simply purchasing drones. It requires addressing various practical challenges, from regulatory compliance and data management to staff training.

Navigating Regulatory Compliance and Certification

One of the first hurdles involves navigating drone regulations. Obtaining necessary certifications for both pilots and aircraft, in accordance with regulations set by aviation authorities like the Federal Aviation Administration (FAA), is crucial. These regulations can vary by region.

Understanding airspace restrictions and obtaining permits for specific flight operations is also essential for ensuring the safe and legal operation of powerline inspection UAVs. This proactive approach helps mitigate potential risks and ensures compliance.

Managing Data and Integration Challenges

Another significant challenge is managing the sheer volume of data generated during inspections. Efficient data storage, processing, and analysis are vital for extracting valuable insights.

Integrating this data with existing asset management systems, such as those offered by IBM Maximo, can be complex. However, this integration is essential for streamlining workflows and maximizing the value of the collected data.

Addressing Operational Limitations

Operational limitations also require careful consideration. Flight time constraints, electromagnetic interference near powerlines, and weather conditions can all impact inspection schedules.

Utilities are developing mitigation strategies. Using multiple batteries and quick-swap systems can extend flight times. Specialized shielding can protect drones from electromagnetic interference. Careful flight planning with tools like AirMap helps minimize weather-related disruptions. For more information, check out our guide on upcoming drone events.

Building Organizational Buy-In and Training

Successful UAV program implementation requires organizational buy-in. Demonstrating the value of drone technology to stakeholders and securing funding are critical first steps.

Training inspection teams to operate drones effectively is equally important. This involves developing comprehensive training programs covering flight operations and data analysis, transforming them into skilled drone operators.

Creating Effective Training Programs

Effective training programs often include these key components:

Basic Flight Training: This covers fundamental drone operation procedures.

Advanced Flight Techniques: This focuses on maneuvering around obstacles like powerlines.

Sensor Operation and Data Acquisition: This trains personnel on using specialized sensors to collect high-quality data.

Data Analysis and Interpretation: This teaches how to extract meaningful insights from the data for maintenance decisions.

Safety Protocols: This emphasizes safe operating procedures and risk mitigation.

Investing in thorough training ensures teams can maximize the potential of powerline inspection UAVs. This comprehensive approach to the human element ensures a smooth transition and maximizes the benefits of this technology. This training investment is crucial for a sustainable and successful program.

Global Adoption Patterns of Powerline Inspection UAVs

Powerline inspection UAVs are reshaping how utility companies manage their infrastructure worldwide. This change isn't happening at the same speed everywhere. Different regions are adopting these technologies at varying rates, shaped by local conditions and specific circumstances.

Regional Differences in UAV Adoption

In developed markets like North America and Europe, the adoption of powerline inspection UAVs has been swift. These regions often have established regulatory frameworks and infrastructure that support implementation. Existing grid operators and maintenance procedures, for example, make integrating drone technology smoother.

However, rapidly developing regions in Asia and other areas are catching up. The need for resilient power networks, along with the opportunity to bypass older infrastructure costs, is driving this adoption. These regions are often skipping older methods and embracing UAVs as a core part of modernization efforts.

The Influence of Infrastructure Needs and Regulations

UAV adoption is closely tied to local needs and regulations. In areas with aging and extensive infrastructure, regular inspections are vital. The efficiency and safety benefits of UAVs are especially appealing in these situations.

Regulatory environments also play a major role. Clear regulations encourage investment, while unclear or restrictive rules can slow things down. This is especially important for emerging markets where regulations are still being developed.

To illustrate the regional variations in the powerline inspection UAV market, the following table provides a snapshot of market size, growth, key players, and the regulatory environment.

To better understand the regional dynamics of this market, let's look at a breakdown by region. The table below provides a summary of key aspects influencing the powerline inspection UAV sector in various parts of the world.

Region | Market Size | CAGR | Notable Regional Players | Regulatory Environment |

|---|---|---|---|---|

North America | XX Billion | XX% | Numerous established drone providers and service companies | Generally well-defined, promoting growth |

Europe | XX Billion | XX% | Mix of established players and emerging startups | Developing frameworks with variations across countries |

Asia | XX Billion | XX% | Rapid growth with key players like Xi'an LingKong Electronic Technology and SIRON Deluge Services | Focus on developing clear regulations to support growth |

Rest of World | XX Billion | XX% | Emerging players catering to specific regional needs | Regulations vary significantly, posing both challenges and opportunities |

This table highlights the diverse landscape of the powerline inspection UAV market. While North America and Europe currently hold significant market share, the rapid growth in Asia indicates a shift in the coming years. Regulatory environments play a critical role in shaping this market, with clearer frameworks fostering greater investment and adoption.

The adoption curve has accelerated significantly since 2020. The compound annual growth rate (CAGR) for powerline inspection drones is estimated to be between 15.7% (for the broader drone inspection market) and even higher for specialized power line segments through 2030. Regional expansion is a major driver. Asian markets, featuring companies like China's Xi'an LingKong Electronic Technology and India's SIRON Deluge Services, are emerging alongside western industry leaders. Discover more insights about this growth here. You might be interested in: our sitemap for additional information.

International Collaboration and Technology Transfer

As this technology matures, international standards and collaborations become increasingly vital. Sharing best practices and technical knowledge between regions helps speed up development. This collaborative approach encourages innovation and ensures interoperability across the industry.

This collaboration is also key for technology transfer. Expertise from developed regions helps emerging economies implement effective UAV programs. This knowledge transfer accelerates adoption and promotes the development of global best practices for powerline inspection.

The Future of Powerline Inspection UAV Innovation

The field of powerline inspection using UAVs (Unmanned Aerial Vehicles) is constantly evolving. Driven by technological advancements and the need for safer, more efficient inspections, UAVs promise to reshape how we maintain our energy infrastructure.

Autonomous Flight and AI-Powered Inspections

One significant development is autonomous flight. Artificial intelligence (AI) allows UAVs to perform inspections without direct human control. This reduces labor costs and expands coverage. Imagine a fleet of drones autonomously inspecting hundreds of miles of powerlines – it's becoming a reality.

AI is also used for data analysis. Algorithms can identify defects like damaged insulators or vegetation encroachment, streamlining the inspection process.

Edge Computing and Real-Time Analytics

Edge computing is another exciting development. Traditionally, data analysis happened after the drone landed. Now, edge computing enables real-time analytics during flight.

This allows for immediate identification of critical issues, enabling faster response times and preventing outages. This is particularly important in remote or hard-to-reach areas.

Drone Swarms and Coordinated Inspections

Drone swarm technology holds immense potential. Multiple specialized UAVs can work together, each with different sensors and tasks. One drone might use visual inspection, another thermal imaging, and a third LiDAR (Light Detection and Ranging).

This coordinated approach allows for comprehensive inspections, covering larger areas with greater efficiency. One drone could inspect powerlines while another checks towers for structural integrity.

Smart Grid Integration and Continuous Monitoring

Finally, integrating UAVs with smart grid technologies is transforming grid management. Modern inspection drones with IoT (Internet of Things) connectivity allow for continuous monitoring. Read the full research here.

Instead of periodic checks, UAVs provide real-time data on grid health and performance. This allows utilities to anticipate problems and optimize energy distribution, improving grid resilience.

Read also: Our blog category sitemap for more insightful content.

The future of powerline inspection is linked to UAV technology. These innovations are not just about efficiency; they're about a more reliable power grid.

Ready to take your powerline inspections to the next level? Learn more at https://www.jabdrone.com.