Drone Power Line Inspection: Complete Industry Guide

- James Baptiste

- May 31, 2025

- 11 min read

Updated: Jun 2, 2025

Why Smart Utilities Are Making The Switch To Drones

The power industry is transforming how it inspects its infrastructure. Drone power line inspection is quickly becoming the go-to method, offering a compelling combination of safety, efficiency, and high-quality data. This shift reflects a broader move towards smart grid management, prioritizing proactive maintenance and optimized resource allocation.

Enhanced Safety For Inspection Crews

Traditional power line inspections often involve dangerous tasks such as climbing towers or using helicopters. These methods put crews at risk, including falls, electrical shocks, and bad weather. Drones, however, remove the need for workers to be physically present in these hazardous situations. Inspections are conducted remotely, greatly reducing the risk of injury and improving overall safety.

Streamlined Efficiency and Cost Savings

Drone inspections offer significant time and cost savings compared to traditional methods. A helicopter inspection, for instance, can take several days and cost thousands of dollars per tower. Drones can complete the same inspection much faster and at a considerably lower cost. This leads to quicker maintenance and better budget allocation for utilities.

This increased efficiency also allows for more frequent inspections. This enables proactive identification of potential problems before they become serious issues. You can explore more about this in this article: Safe and cost-effective utility solutions using UAVs for power line inspection.

Superior Data Quality and Actionable Insights

Modern drones have advanced sensors, including high-resolution cameras, thermal imaging, and LiDAR, which deliver detailed data surpassing traditional methods. This technology captures intricate infrastructure details, detects heat anomalies, and creates accurate 3D models.

This rich data provides a thorough understanding of a power line’s condition, enabling targeted maintenance and improved grid reliability. The data is often enhanced by AI-powered analysis, which automates defect detection and gives actionable insights to maintenance teams. This helps utilities shift from reactive repairs to proactive maintenance, minimizing downtime and providing a more reliable power supply.

Furthermore, the global drone power line inspection market is booming. In 2024, the market was valued at about USD 26.66 billion. Projections indicate it could reach USD 323.8 billion by 2032. This represents a substantial compound annual growth rate (CAGR) of 36.63%, highlighting the increasing importance of this technology. More detailed statistics can be found here.

Choosing The Right Drone Technology For Your Needs

Power line inspections are more efficient and safer with drones. However, not all drone systems are equal. Choosing the right technology involves understanding your inspection needs and the challenges posed by the terrain. Selecting the correct drone and sensor payload is crucial for gathering the most valuable data and maximizing efficiency.

Drone Types: Fixed-Wing, Multi-Rotor, and Hybrid

The drone market offers a variety of platforms, each designed for different tasks. Fixed-wing drones are like small airplanes. Their strength lies in covering large distances rapidly, making them suitable for inspecting long transmission lines. The trade-off is that they need open space for takeoff and landing.

Multi-rotor drones offer excellent maneuverability and can hover precisely, allowing for detailed close-ups of individual components. This makes them well-suited for inspecting intricate structures like substations. However, shorter flight times can limit their use over vast areas.

Hybrid VTOL (Vertical Take-Off and Landing) drones bridge the gap between fixed-wing and multi-rotor. They combine the long-range flight of fixed-wing aircraft with the vertical takeoff and landing of multi-rotors. While versatile, these drones often come with a higher price tag. Therefore, carefully consider their cost-effectiveness for each project. The drone power line inspection market continues to evolve, with fixed-wing, multi-rotor, and hybrid VTOL models offering specialized solutions. Learn more about this evolving market at Archive Market Research.

Sensor Technologies: Seeing Beyond the Visible

The sensor payload is just as important as the drone itself. It dramatically affects the quality and type of data collected. High-resolution optical cameras provide detailed visual inspections, capturing images and videos of potential damage. Thermal imaging cameras detect heat anomalies, helping identify overheating components and potential electrical faults before they lead to major failures. Learn more in this helpful guide: Understanding Drone Sensors and Camera Capabilities.

LiDAR systems create precise 3D models of power lines and the surrounding environment. These models enable accurate measurements and analysis of vegetation encroachment, tower stability, and other critical factors impacting line health. For more detailed information on power line inspections with drones, see How to Master Power Line Inspections with Drones. Choosing the best sensor combination depends on your inspection goals and budget. Each sensor type offers unique advantages, making selecting the appropriate technology crucial for a successful inspection program.

Building A Drone Inspection Program That Actually Works

Moving from traditional methods to drone power line inspection requires a well-defined strategy. Simply purchasing drones won't get the job done. A truly successful program requires careful planning, meticulous execution, and a commitment to ongoing adaptation.

Key Steps To Building A Successful Program

Implementing a drone-based power line inspection program involves several crucial components:

Regulatory Compliance: Understanding and complying with all applicable regulations is essential. This includes obtaining proper pilot certification (such as Part 107 in the US) and securing necessary airspace authorizations.

Pilot Training: Highly skilled drone pilots are a must. Thorough training ensures safe drone operation, acquisition of high-quality data, and the development of efficient inspection workflows. Training should specifically encompass power line inspection techniques.

Data Management: A robust data management strategy is critical. This includes data storage, processing, analysis, and seamless integration with existing asset management systems.

Workflow Integration: Integrating drone operations smoothly into current maintenance workflows is key for maximizing the program's effectiveness. This involves connecting the newly acquired inspection data to your existing asset management systems.

These foundational elements will contribute to reliable results and ensure a solid return on investment.

Structuring Your Team and Operations

Many organizations aspire to build an internal drone team over the long term. However, partnering with experienced drone service providers initially can be an excellent starting point. This allows utilities to gain practical experience with drone power line inspections before committing to significant capital investments.

Regardless of whether you choose to develop in-house capabilities or outsource, a well-defined organizational structure is vital. Clearly defined roles, responsibilities, and communication protocols are essential for streamlined and efficient operations. This also includes establishing stringent quality control procedures to maintain data accuracy and consistency.

Budgeting and Vendor Selection

Developing a realistic budget is paramount. Factor in not only the initial drone purchase costs, but also ongoing expenses such as maintenance, insurance, software, and personnel. Choosing vendors who align with your long-term objectives is equally important. Look for providers who offer continuous support and can adapt to your evolving needs.

Successfully implementing a drone power line inspection program also requires addressing potential internal resistance. Clearly demonstrating the program's advantages – such as improved safety, significant cost savings, and enhanced data quality – can help secure buy-in from key stakeholders. Proactively addressing concerns and showcasing early successes builds confidence and paves the way for wider adoption.

Advanced Inspection Methods That Maximize Your Investment

Modern drone power line inspection offers more than just visual data. Strategically implemented, it becomes a powerful tool, delivering significant value and maximizing ROI. Top utilities leverage advanced methods to achieve these results.

Targeted Inspection Strategies For Specific Needs

Different inspection scenarios require different approaches. Scope inspections provide efficient routine monitoring, quickly covering large areas to identify potential issues. This method is perfect for regular line patrols and general assessments.

Fixed-point inspections focus on capturing detailed data about specific components. This is particularly useful for assessing critical infrastructure like transformers and insulators, ensuring accurate condition assessments.

For high-value assets or areas needing thorough evaluation, comprehensive inspections provide the most detailed analysis. These combine various data sources and often incorporate advanced analytics for a complete understanding of asset health.

The Power of AI and Machine Learning

Artificial intelligence (AI) and machine learning are transforming drone inspection data analysis. Automated defect detection algorithms can identify problems human inspectors might miss, improving accuracy and efficiency. This means catching subtle signs of corrosion, vegetation encroachment, or component wear earlier, allowing for proactive maintenance.

This leads directly to more predictive maintenance strategies. Analyzing data trends over time, AI can identify patterns indicating potential future failures. For example, by tracking connector corrosion rates, algorithms can predict likely failure times, allowing timely replacement before outages occur. This proactive approach improves grid reliability and minimizes costly reactive repairs. This data-driven approach optimizes maintenance schedules and reduces unexpected downtime.

What Regional Markets Reveal About Implementation Success

Drone power line inspection is steadily gaining popularity worldwide. However, the speed of adoption differs significantly from one region to the next. Understanding these regional variations is essential for designing an effective drone program. Factors like regulations, infrastructure requirements, and market maturity all influence how drone technology is implemented and the outcomes it delivers.

North America: Leading the Charge

North America is a pioneer in drone power line inspection. This is primarily due to the region’s aging infrastructure, which necessitates regular and detailed inspections to maintain a reliable power grid. Furthermore, supportive regulatory frameworks have encouraged innovation and prompted utility companies to explore drone solutions. The widespread adoption of drones by utilities seeking safer and more efficient inspection methods has fueled this growth.

Europe: A Focus on Sustainability

European markets are also embracing drone power line inspections, often prioritizing environmental concerns. Progressive policies designed to reduce carbon emissions and encourage sustainable practices have made drones a compelling alternative to traditional methods. This trend is bolstered by strong industry demand for more efficient and cost-effective inspection solutions. As of 2025, North America holds the largest market share, followed by Europe and then Asia-Pacific. More detailed statistics can be found here: Archive Market Research.

Asia-Pacific: Rapid Growth and Unique Challenges

The Asia-Pacific region is experiencing rapid growth in drone power line inspection, particularly in countries like China and India. Large-scale infrastructure projects and rising energy demands are driving the need for efficient inspection methods. However, diverse regulatory landscapes and varying levels of technological development present unique challenges for implementing drone programs.

Adapting Strategies to Regional Nuances

These regional differences offer valuable insights. Understanding which regulatory environments support faster deployment, or how varying market conditions influence program design, can be invaluable in shaping your approach. For example, North America’s experience with regulatory support can offer a roadmap for other regions. Meanwhile, Europe’s focus on sustainability underscores the wider advantages of drone inspections.

Choosing the right equipment and vendors also hinges on regional factors. A vendor with a strong local presence and support in your target market might be preferable to a globally recognized brand with less regional expertise. Drone selection should also consider the specific challenges and regulations within your operational area. Ultimately, tailoring your drone power line inspection strategy to the specific regional context is crucial for maximizing success.

Real Numbers: What Drone Inspection Actually Costs

Understanding the true financial implications of drone-based power line inspections is essential for any organization considering this technology. It's more than just buying a drone; it's about understanding the complete picture. This includes training, maintenance, insurance, and the day-to-day operational costs. We'll break down these expenses and then compare them to traditional methods, like using helicopters or ground crews, to highlight the potential return on investment.

Breaking Down the Costs of Drone Inspection

Several key expenses contribute to the overall cost of implementing a drone inspection program:

Initial Investment: This covers the drone itself, plus necessary accessories like batteries, chargers, and cases. Depending on the features and quality needed for professional inspections, drones can cost from a few thousand dollars to tens of thousands.

Training: Certified pilot training is essential. These programs teach safe and efficient drone operation, directly impacting the quality of the data collected. The cost varies depending on the specific program and desired certification level.

Maintenance: Regular maintenance is crucial for optimal drone performance. This includes routine checks, repairs, and part replacements, much like maintaining any other type of equipment.

Insurance: Drone insurance is highly recommended to protect your investment. Coverage should include potential drone damage, liability in case of accidents, and any associated legal fees. For more details on protecting your business, consult our guide on drone business insurance.

Operational Costs: These are the recurring costs associated with each inspection. They include staff time, travel to inspection sites, data processing, and software subscriptions.

Comparing Costs: Drones vs. Traditional Methods

To illustrate the cost differences between drone inspections and traditional methods, let's look at the following comparison.

To better visualize the cost differences between these inspection methods, the table below provides a detailed comparison.

Drone vs Traditional Inspection Cost Comparison: A detailed comparison of costs between drone-based and traditional power line inspection methods

Inspection Method | Initial Investment | Cost Per Mile | Safety Risk | Data Quality |

|---|---|---|---|---|

Drone | $5,000 - $20,000+ | $50 - $150 | Low | High |

Helicopter | $1,000,000+ | $500 - $1,500+ | High | Medium |

Ground Crew | $10,000 - $50,000 | $100 - $300 | Medium | Low |

As the table demonstrates, while the initial investment for drones might seem significant, the cost per mile is substantially lower than helicopters. Drones also offer a considerable safety advantage and deliver higher quality data.

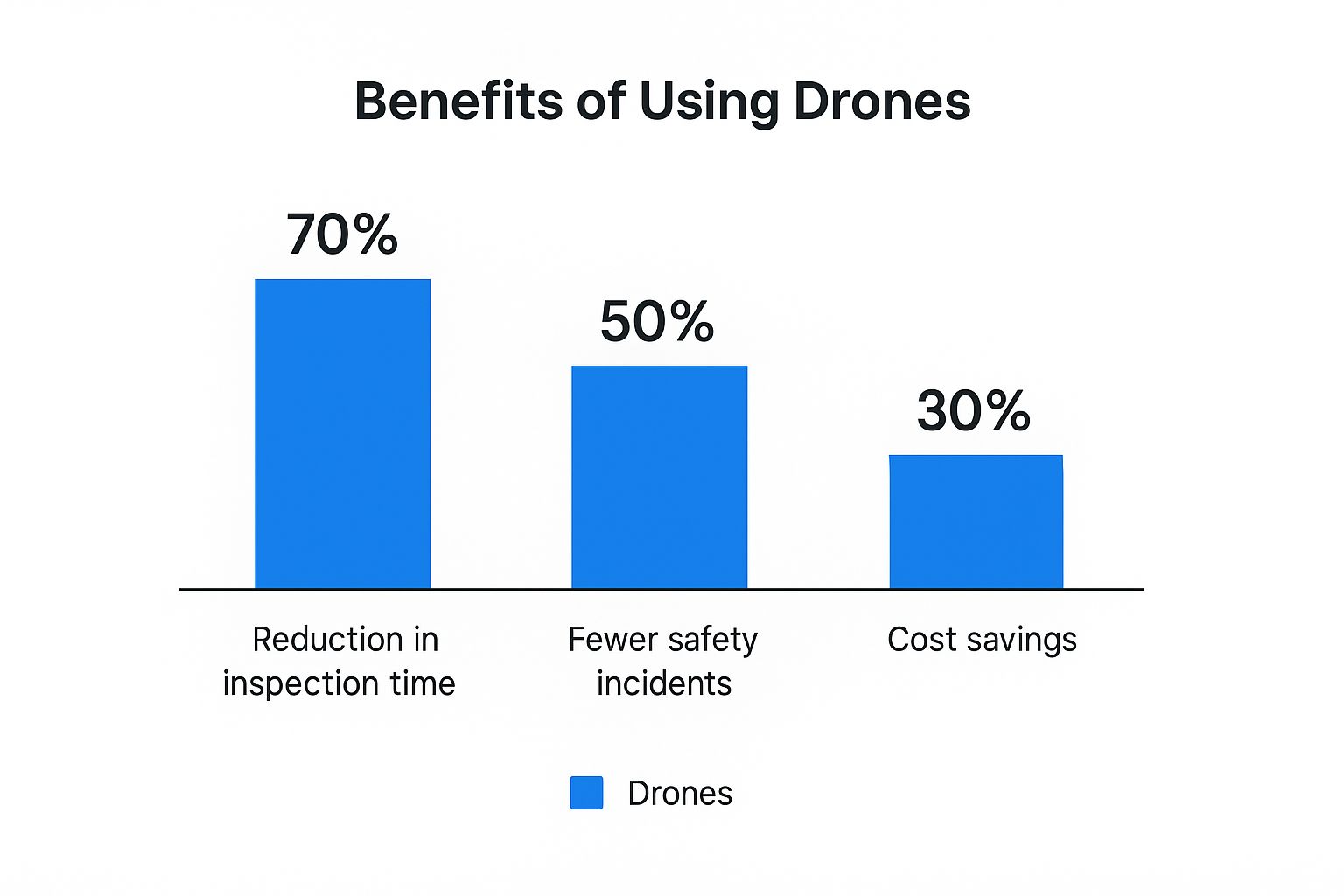

The infographic below further emphasizes these key data points.

Drones offer a 70% reduction in inspection time, 50% fewer safety incidents, and overall cost savings of 30%.

Calculating Return on Investment (ROI)

Calculating the ROI of a drone program requires a comprehensive approach. This means considering not only the reduced inspection time and lower direct costs, but also the less obvious advantages. Improved safety significantly minimizes the risk of accidents and worker compensation claims. Higher quality data facilitates more precise maintenance, preventing major equipment failures and costly emergency repairs. Early problem detection improves grid reliability, increasing customer satisfaction and ensuring regulatory compliance.

By factoring in all these benefits, organizations can often demonstrate a reasonable payback period and substantial long-term savings. The focus should be on a strategic, long-term approach, not just the initial cost of the technology. This forward-thinking mindset helps justify the investment and ensures long-term success in maintaining a safe and efficient power grid.

Where The Industry Is Heading Next

The drone power line inspection market is constantly evolving, creating exciting opportunities for utilities willing to adapt and embrace new technologies. Staying informed about these advancements is key to improving inspection processes, enhancing safety, and maximizing value.

Drone-as-a-Service and Expanding Access

Drone-as-a-Service (DaaS) is changing how utilities access drone technology. This model allows smaller utilities to leverage advanced inspection capabilities without the substantial upfront investment in equipment or specialized staff. DaaS providers handle all aspects of the operation, from pilot training and drone maintenance to data analysis, making these technologies accessible to a wider range of organizations.

Technological Advancements Driving Change

Several key technologies are pushing drone power line inspections forward. Autonomous flight systems reduce the need for manual piloting, allowing drones to follow pre-programmed flight paths. This increases both efficiency and data consistency. To learn more, check out our guide on the latest drone innovations: The Latest Drone Technology Innovations and Trends to Watch.

Improved battery technology allows drones to fly longer, covering more ground in a single mission. This helps reduce operational costs and improves the feasibility of inspecting remote areas. AI-powered analysis automates defect detection, catching subtle problems that might be missed by human inspectors. This enhances accuracy and frees up personnel for other critical tasks.

The following table summarizes projected market growth for various applications of drone inspections in the energy sector:

Market Growth Projections by Application

Application | Current Market Value | Projected Growth Rate | Key Drivers |

|---|---|---|---|

Power Line Inspection | X Billion | X% | Increasing need for efficient and safe inspections, rising adoption of AI-powered analysis |

Vegetation Management | Y Billion | Y% | Growing demand for preventative maintenance, increasing focus on wildfire mitigation |

Wildlife Monitoring | Z Billion | Z% | Heightened awareness of environmental impact, regulations related to wildlife protection |

Emergency Response Coordination | W Billion | W% | Need for rapid damage assessment after natural disasters, demand for real-time situational awareness |

Note: Replace X, Y, Z, and W with estimated market values and growth rates relevant to the industry. Accurate data is crucial for a table like this.

This table highlights the expanding role of drones in the energy sector, moving beyond simple inspections to encompass diverse applications.

Emerging Applications and Expanding Value

Drone power line inspection is no longer limited to checking for damaged wires. Emerging applications are significantly expanding its value. Drones are now used for vegetation management, identifying encroaching trees to plan targeted trimming, and for wildlife monitoring, observing bird nests near power lines to assess environmental impact. They are also being used for emergency response coordination, providing real-time situational awareness after storms or natural disasters to quickly assess damage and restore power.

Regulatory Landscape and Industry Standards

Evolving regulations and industry standards are also shaping the future of drone inspections. As governing bodies refine drone usage guidelines, they create a more predictable and supportive environment for wider adoption. This encourages more sophisticated drone operations and integration with other grid management systems.

The drone inspection market is experiencing rapid growth. The overall drone inspection and monitoring market was valued at US$16.4 billion in 2024 and is projected to reach US$38.2 billion by 2030. The power line inspection sector is growing even faster. You can find more details in this report: Drone Inspection and Monitoring Global Market Report.

The convergence of these factors points to a future where drone power line inspection is essential for utility operations. This future promises data-driven insights leading to proactive maintenance, increased reliability, and improved safety for both personnel and the environment.

Want to elevate your power line inspections? Explore the world of drones at JAB Drone and discover how they can transform your operations.

Comments