Discover the Power of Drone Brushless Motor: The Ultimate Guide

- James Baptiste

- Jul 30, 2025

- 17 min read

A drone brushless motor is the high-performance heart of any modern quadcopter, single-handedly dictating its power, speed, and endurance. It's not just a part; it's the engine in a race car, the core of an athlete. Its efficiency and strength are the most critical factors for achieving peak performance, from breathtaking agility to long, stable flights.

Why The Brushless Motor Is The Heart Of Your Drone

Every impressive move a drone makes—from a rapid, gut-wrenching ascent to a smooth, cinematic pan—is powered by these compact, potent devices. A drone brushless motor is an electric motor that works without the physical "brushes" you'd find in older, more traditional motor types. This one design difference is the secret behind their superior performance.

By getting rid of those brushes, these motors drastically cut down on friction and wear and tear. That simple change unlocks a whole host of benefits that have completely remade the drone industry. Less friction means less energy is wasted as heat, leading to much, much higher efficiency.

For any drone pilot, getting a handle on brushless motors is non-negotiable. They are the single most important component influencing how your drone flies, how long it stays in the air, and what it’s truly capable of.

The Impact On Flight Performance

This incredible efficiency translates directly into longer flight times, since more of the battery's juice is converted into pure rotational force. It's the reason a modern drone can stay airborne for 30 minutes or more, while older models were lucky to hit 10.

But it doesn't stop there. The power-to-weight ratio of a drone brushless motor is just exceptional. They pack immense torque and speed into a tiny, lightweight package, giving you the raw strength needed for just about anything.

High-Speed Agility: In FPV racing, pilots live and die by the motor's ability to change RPMs in the blink of an eye for hairpin turns and explosive acceleration.

Smooth Cinematic Shots: For aerial photographers, consistent and stable motor performance is what delivers that buttery-smooth footage without annoying jitters or vibrations.

Heavy Lifting: Commercial drones tasked with carrying heavy sensors or delivery packages rely on the brute force of powerful brushless motors to get off the ground and fly safely.

To really see the difference, it helps to put the two motor types side-by-side.

Brushless vs. Brushed Drone Motors at a Glance

Here’s a quick breakdown of how brushless motors stack up against their older, brushed counterparts. The advantages become pretty clear, pretty fast.

Feature | Brushless Motor | Brushed Motor |

|---|---|---|

Efficiency | Very High (85-90%) | Lower (75-80%) |

Lifespan | Long (10,000+ hours) | Short (1,000-3,000 hours) |

Maintenance | Virtually none | Regular brush replacement |

Speed/Torque | High and consistent | Lower, prone to wear |

Cost | Higher initial cost | Lower initial cost |

Control | Precise speed control via ESC | Simpler, less precise control |

As you can see, while brushed motors might be cheaper upfront, the long-term performance, reliability, and lifespan of brushless motors make them the obvious choice for any serious application.

Market Dominance and Reliability

The benefits are so overwhelming that the industry has almost universally jumped on board. Today, brushless motors completely dominate the drone motor scene, accounting for roughly 86.1% of the market share.

Their widespread adoption is all thanks to that superior energy efficiency, lightweight build, and rock-solid reliability compared to brushed motors. These traits are what push flight times further and improve the kind of operational accuracy that's absolutely vital for commercial jobs. If you want to dig deeper into the numbers, you can find more on these drone motor market trends on futuremarketinsights.com.

Ultimately, whether you're building a custom FPV quad from scratch or picking up a ready-to-fly cinematic drone, the brushless motors are the core components that will define your entire experience. They are the powerhouse that makes modern drone flight possible.

How a Drone Brushless Motor Actually Works

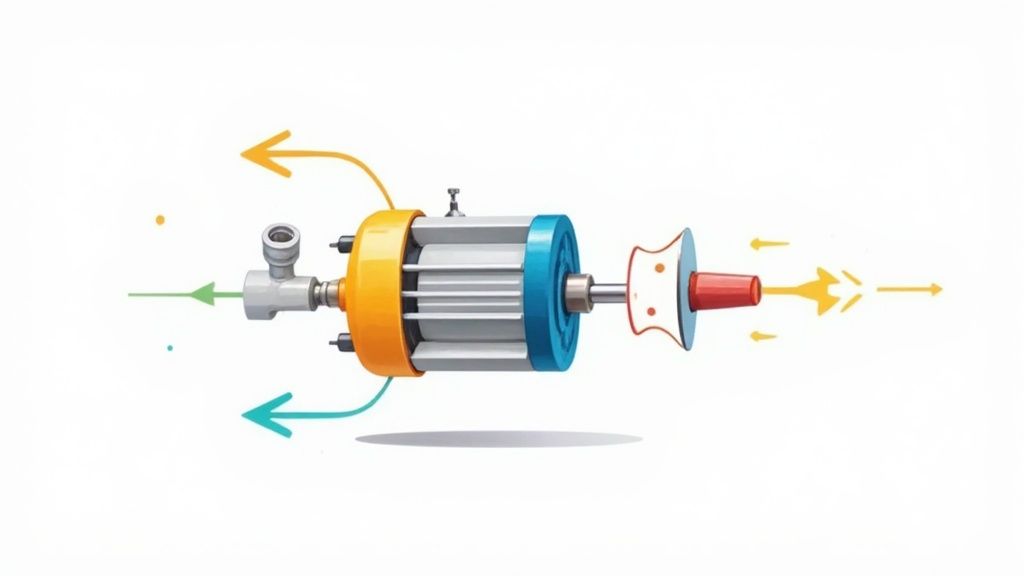

To get your head around how a drone brushless motor actually hauls a quadcopter into the sky, you don't need a physics degree. The concept is surprisingly elegant. Just picture a spinning magnet that's always chasing an invisible, rotating magnetic field. This endless game of cat and mouse is what generates the serious rotational force—or torque—that a drone needs to fly.

At its core, a brushless motor is all about the magic of electromagnetism. It's a beautifully timed dance between electromagnets that stand still and powerful permanent magnets that spin. When you run electricity through a wire, it creates a magnetic field. By smartly controlling that flow, you can create motion.

This whole process is way more efficient and reliable than the old-school brushed motors. Those relied on physical contacts that caused friction, created a ton of heat, and eventually wore out. By getting rid of these failure points, the brushless design gives you a motor that lasts longer and performs much, much better.

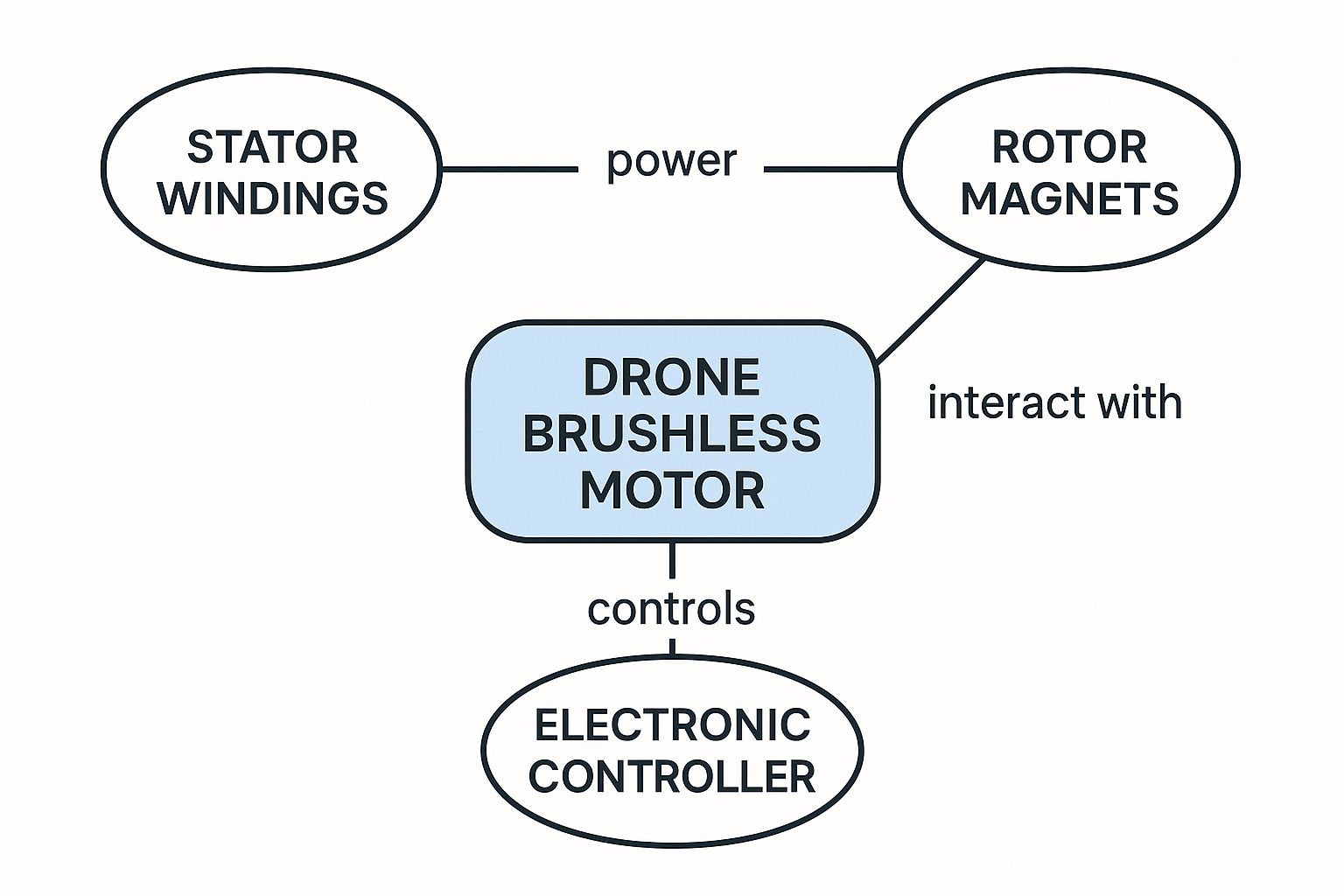

The Key Players: Stator, Rotor, and ESC

To really get it, you need to meet the three main components that work together in perfect sync. Each one has a critical job in turning electrical energy from your battery into the spinning force that gets your props moving.

The Stator: This is the stationary heart of the motor. It’s built from a stack of thin metal plates and wrapped with super-tight copper coils. When electricity zips through these coils, they turn into powerful electromagnets. The stator is the fixed foundation that creates the rotating magnetic field.

The Rotor (or Bell): This is the part that actually spins. The motor's outer shell, which we often call the bell, is lined with strong permanent magnets on its inner wall. The rotor fits right over the stator, and its magnets are the ones that get dragged along by the stator's shifting magnetic field.

The Electronic Speed Controller (ESC): You can think of the ESC as the motor's brain. It’s a separate little circuit board that takes orders from the drone’s flight controller. It then sends perfectly timed pulses of electricity to the stator's coils, energizing them in a specific sequence to create that rotating magnetic field the rotor's magnets just can't help but follow.

This concept map breaks down how these three crucial parts interact to create controlled rotation.

As you can see, it's a constant loop: the ESC tells the stator what to do, the stator's magnetic field makes the rotor spin, and that spin is what powers your drone.

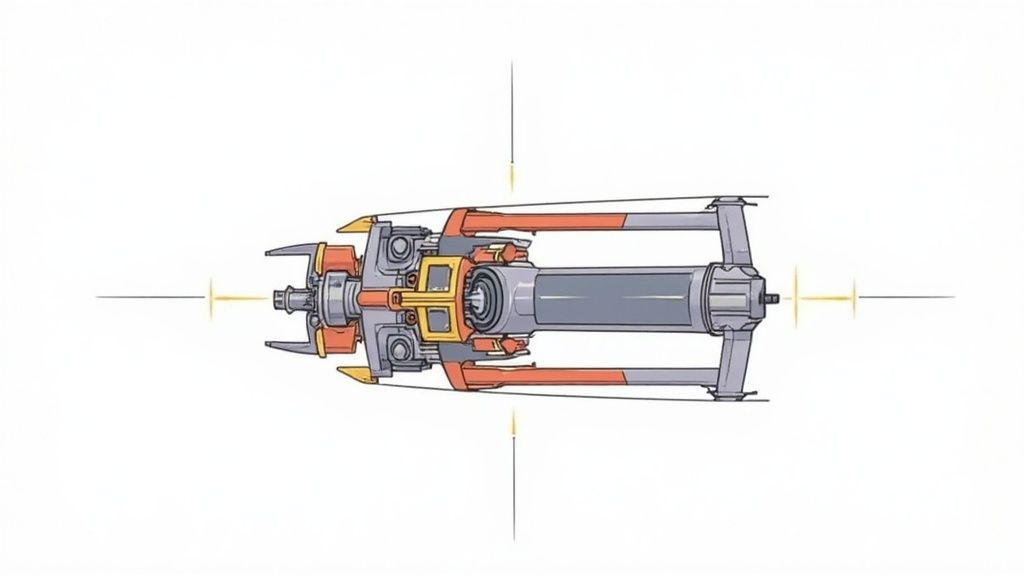

The Outrunner Advantage for Drones

Brushless motors generally come in two flavors, and for drones, the choice is a no-brainer. The design used in pretty much every multirotor drone out there is the outrunner.

In an outrunner motor, the outer can—the rotor with all the magnets—spins around the stationary inner core, the stator. This setup delivers a ton more torque at lower RPMs, which is exactly what you need for spinning big propellers directly without a clunky, heavy gearbox.

This high-torque output is precisely why outrunners are the kings of the drone world. They give you the raw, instant power needed to get off the ground and make the lightning-fast RPM changes required for rock-solid stability and nimble flying.

The other option is the inrunner motor, where the rotor spins inside a stationary outer can. Inrunners are great at hitting ridiculously high RPMs but don't produce nearly as much torque. You'll find them more often in things like RC cars or planes where sheer speed is the goal, not the brute lifting force a quadcopter demands. The choice to use an outrunner design is a big part of what makes a drone brushless motor so compact yet so incredibly powerful.

Decoding Motor Specs: What the Numbers Mean

When you first start looking at drone brushless motors, it can feel like you’re trying to crack a secret code. You're hit with a string of letters and numbers like "2207-1950KV," which, at first glance, might as well be nonsense. But those specs are everything—they tell you the motor's story and are the key to matching it perfectly with your drone and what you want to do with it.

Think of these numbers as a motor's stat sheet. A good FPV pilot or builder knows how to read these stats to predict exactly how their quad will handle in the air. Let's break down this code piece by piece, so you can pick your next set of motors with confidence.

Understanding Motor Size: The 2207 Example

The first number you'll almost always see, like 2207 or 2306, tells you the physical size of the motor's stator. The stator is the fixed, copper-wound core inside the motor, and its dimensions have a huge impact on the motor's torque and power.

Let's use a 2207 motor as our guide:

22 (Stator Diameter): The first two digits are the stator's diameter in millimeters. A wider stator generally cranks out more torque, which is the raw twisting force needed to spin props—especially big, aggressive ones.

07 (Stator Height): The last two digits tell you the stator's height in millimeters. A taller stator often helps a motor get up to high RPMs more efficiently.

So, a 2207 motor has a stator that is 22mm wide and 7mm tall. This is a big deal because a larger overall stator volume (width and height combined) usually means more power. For example, a 2306 motor (23mm wide, 6mm tall) will have a slightly different feel and power curve than a 2207, often leaning more towards torque because it's wider.

A great way to think about it is that stator volume is like engine displacement in a car. A bigger engine (larger stator) can make more power, but it's also going to be heavier and pull more juice from your battery.

The Mystery of KV Rating Explained

The other number that's absolutely critical is the KV rating, like 1950KV or 2400KV. This is a common point of confusion—it has nothing to do with kilovolts. The KV rating simply tells you a motor's theoretical speed, without a propeller, for every volt you feed it.

A motor rated at 1950KV will try to spin at 1,950 revolutions per minute (RPM) for every one volt of electricity. So if you're running a common 6S LiPo battery (which sits around 24 volts), that motor is aiming for a blistering top speed of 46,800 RPM (1950 x 24).

It helps to think of KV rating like the gears on a bike:

Low KV (e.g., 1700KV): This is your low gear. It gives you more torque and is super efficient at spinning large, heavy props. You'll find these motors on long-range cinematic rigs or heavy lifters where flight time and smooth control are king.

High KV (e.g., 2500KV): This is your high gear. It’s all about speed and snappy response, designed to spin smaller props at insane speeds. This is the sweet spot for FPV racing and aggressive freestyle drones.

Don't fall into the trap of thinking higher KV means more power. Power is a combination of both torque and RPM. The KV rating just tells you how a motor is wound and what it's optimized for—the right props and the right battery voltage.

Reading a Motor Thrust Data Chart

The last piece of the puzzle is the manufacturer's thrust data chart. This table is your ultimate cheat sheet, taking all the theory and showing you exactly how a motor performs in the real world with different props and batteries. It cuts through all the guesswork.

These charts will typically lay out:

Propeller Size and Pitch: The exact prop model they used for testing.

Voltage: The battery voltage, usually 4S or 6S.

Thrust (grams): How much lift the motor generates at various throttle points.

Current Draw (Amps): How much power the motor is sucking from the battery.

Efficiency (g/W): How many grams of thrust it produces for every watt of power used.

Learning to read these charts is what separates rookies from seasoned builders. By digging into this data, you can find the perfect "sweet spot" for your build, striking that ideal balance between raw power and decent flight time.

Choosing the Right Motor for Your Drone Build

Now that you have a solid handle on motor specs, it's time to put that knowledge to work. Picking the perfect drone brushless motor isn't about grabbing the one with the biggest numbers. It’s a strategic choice that needs to align with what your drone is built to do. After all, the ideal motor for a screaming FPV racing quad would be an awful fit for a smooth, long-range cinematic platform.

This isn't just about the motor, though. You have to think of your entire power system—the motor, propeller, and battery—as a single, interconnected team. When these three work in harmony, you get peak performance. When they're mismatched, you're in for a world of hurt: poor flight characteristics, terrible efficiency, and maybe even a few fried components.

Let's break down how to choose the right motor for three of the most common drone builds.

Scenario 1: The High-Speed FPV Racing Drone

For an FPV racing drone, every millisecond is precious. The name of the game is pure, unadulterated speed and instant responsiveness. In this arena, high KV ratings and punchy, powerful motors are king.

You need a motor that can spin up or down in the blink of an eye to carve through hairpin turns and blast out of a dive. This is where motors with a taller stator, like a 2207 or 2306, really come alive. They have the raw muscle to spin aggressive, high-pitch propellers without breaking a sweat.

Motor Size Recommendation: 2207 to 2306

KV Rating Recommendation (6S Battery): 1950KV - 2100KV

KV Rating Recommendation (4S Battery): 2400KV - 2700KV

Propeller Choice: Aggressive 5-inch tri-blade propellers with a higher pitch.

Key Consideration: You're sacrificing flight time and efficiency for maximum thrust and lightning-fast response.

Scenario 2: The Smooth Cinematic Drone

Building a rig to capture buttery-smooth cinematic footage is a whole different ballgame. Here, we're trading raw speed for stability, efficiency, and silky-smooth operation. The main goal is to get rid of any vibration or "jello" that could ruin your video, all while carrying the extra weight of a quality camera.

This is where lower KV motors shine. They deliver the smooth, consistent torque needed to spin larger, more efficient propellers. This combination gives you greater stability and longer flight times—both critical when you're hunting for that perfect shot. A motor with a wider stator, like a 2807, is an excellent choice here for its inherent stability and better heat management.

Motor Size Recommendation: 2306 to 2807

KV Rating Recommendation (6S Battery): 1700KV - 1900KV

Propeller Choice: Less aggressive, high-efficiency 5-inch or 6-inch bi-blade or tri-blade props.

Key Consideration: Smoothness and efficiency trump top-end speed. The motor must provide stable lift for a heavier payload.

Scenario 3: The Long-Range Endurance Build

When you’re building a long-range drone, the mission is simple: stay airborne for as long as humanly possible. Every single component choice is laser-focused on wringing out maximum efficiency. For these builds, low KV motors aren't just a good idea—they're a must.

Low KV motors are naturally more efficient at the lower throttle ranges where a long-range drone spends most of its flight time. They're designed to spin large, highly efficient props (think 7-inch bi-blades) at a slow, steady RPM. This setup generates just enough thrust for a comfortable cruise while barely sipping power from the battery.

The secret to a successful long-range build is achieving the highest possible efficiency, measured in grams of thrust per watt of power (g/W). This metric, found on motor thrust charts, is your most important guide.

Motor Selection for Long-Range (6S Battery):

Motor Size: 2506 to 2808

KV Rating: 1300KV - 1500KV

Propeller Choice: Large, high-efficiency 7-inch bi-blade propellers.

The decision-making process for a drone build is complex, but understanding these fundamental scenarios provides a strong foundation. For those looking to broaden their knowledge from individual components to the entire aircraft, check out our practical guide on [how to choose a drone](https://www.jabdrone.com/post/how-to-choose-a-drone-a-practical-guide), which covers these concepts in a wider context. Ultimately, matching the motor to your propeller and battery voltage is the key to creating a drone that flies exactly how you envision.

Installation and Maintenance Best Practices

A top-tier drone brushless motor is a beautiful thing, but it can only deliver on its promise if it's installed and cared for correctly. Even the most powerful motor will feel sluggish or die an early death if it's mounted poorly or left neglected. Getting the basics right from the start paves the way for countless successful flights, while a quick maintenance routine keeps your drone flying safely and predictably.

It all begins with a rock-solid physical connection to the drone's frame. Make sure the motor is sitting flush on the arm and that every mounting screw is tightened down securely. You'd be surprised how many flight-ruining vibrations come from loose screws. In a worst-case scenario, a motor can even rip itself off mid-air—a truly catastrophic failure.

Next up is the electrical connection to the Electronic Speed Controller (ESC). We're talking about clean, shiny solder joints that are strong and fully insulated with heat shrink. A bad "cold" solder joint is a ticking time bomb; it can easily break loose from vibrations or introduce electrical noise that throws the flight controller into a spin, leading to some very erratic flight behavior.

Essential Installation Checklist

Nailing the initial setup prevents a world of headaches down the line. Before you even think about arming your drone for the first time, run through these critical checks to make sure every motor is good to go.

Secure Mounting: Always use the right length screws for your frame's arm thickness. If the screws are too long, they can hit the motor's internal stator windings, creating a dead short and instantly frying the motor. Too short, and they won't get a proper grip.

Clean Soldering: Pre-tin both the motor wires and the ESC pads before you join them. This simple step ensures you get a quick, solid bond without having to apply excessive heat, which can easily damage the delicate components on the ESC.

Smart Wire Management: Carefully route your motor wires so there’s zero chance they can get nicked by a spinning propeller. Use zip ties or your frame's built-in clips to secure them neatly against the arm, but leave just a little bit of slack to absorb vibrations.

A common myth, especially among new builders, is that you need to oil or lubricate your motor bearings. The truth is, most quality drone motors use sealed bearings that are lubricated for life. Adding outside oil just attracts dirt and grit, which can work its way inside and cause the bearing to fail much faster.

Simple Motor Maintenance Routine

Just like any high-performance machine, your drone's motors will thank you for regular check-ups. This is especially true after a crash, no matter how minor it seemed. This simple routine will help you catch small problems before they become flight-ending disasters.

Making a post-flight check a regular habit is one of the best things any pilot can do. Adding these motor-specific checks is a fast and easy way to boost your drone's safety and reliability. For a full rundown of what to look for, our [drone pre-flight checklist provides essential safety tips](https://www.jabdrone.com/post/drone-pre-flight-checklist-essential-safety-tips) covering the entire aircraft.

Quick Troubleshooting Guide

Even with perfect maintenance, things can still go wrong. Here’s a quick guide to diagnosing some of the most common motor issues you might run into.

Symptom | Possible Cause | How to Fix It |

|---|---|---|

Excessive Vibration | A bent motor shaft, an unbalanced propeller, or a loose mounting screw. | Spin the motor by hand; you'll feel a bent shaft. Check prop balance and re-tighten all screws. |

Motor Overheating | Propeller is too large or has too much pitch for the motor's KV, or the PID tune is too aggressive. | Try a smaller or less aggressive prop. Lower the P and D gains in your flight software. |

Grinding or Rough Noise | A damaged or dirty bearing. | Take the motor bell off and clean the inside with compressed air. If it still sounds rough, the bearing likely needs to be replaced. |

Motor Stuttering | A bad solder joint on the ESC or a desync issue. | Inspect and re-solder the connection. If the problem doesn't go away, it could be a damaged motor winding. |

By following these simple installation and maintenance practices, you're making sure your brushless motors can perform at their absolute best, giving you the power and reliability you need every time you fly.

The Future of Drone Motor Technology

While today's brushless motor is already an engineering marvel, the technology is anything but static. The relentless push for longer flights, heavier payloads, and more intelligent drones is driving motor innovation into some really exciting places. The future isn't just about raw power; it's about making motors smarter, lighter, and more integrated than ever before.

One of the biggest shifts we're seeing is the move toward fully integrated propulsion systems. Think about a motor that doesn't just blindly take orders from the ESC but actually talks back to the flight controller. This two-way conversation will open the door for real-time diagnostics—reporting on temperature, vibration, and efficiency—allowing the drone to make constant micro-adjustments for peak performance.

Smarter Materials and AI Optimization

The physical guts of the brushless motor are also getting a serious upgrade. Researchers are always tinkering with new materials to build lighter and more powerful designs. This includes developing stronger neodymium magnets and advanced alloys for motor bells and stators, which helps them shed heat better while cutting down on overall weight.

A lighter motor means a more nimble drone and longer flight times. It's that simple.

The next real leap, though, is coming from artificial intelligence. AI algorithms will soon be able to optimize motor performance on the fly, tweaking parameters in real-time to smooth out vibrations, quiet the drone, and squeeze every last drop of efficiency out of the battery based on current flight conditions. This doesn't just lead to smoother flights; it's a stepping stone to more autonomous and reliable drone operations.

These advancements aren't just happening in a lab; they're fueling major market growth. The global drone brushless motor market, currently valued at around $2.5 billion, is on track to grow at a compound annual rate of about 15% through 2033. This surge is a direct result of wider drone adoption and these very technological leaps in motor design. You can dig into these market projections on archivemarketresearch.com.

The Path to Greater Autonomy

Ultimately, all these developments are paving the way for more capable and autonomous drones. Smarter motors that can self-diagnose and communicate are a critical piece of the puzzle for building safer, more dependable UAVs. When these advanced motors work in sync with other onboard systems, they dramatically enhance a drone's ability to operate on its own.

This synergy is especially vital for complex missions that demand incredible precision and safety. If you're curious about how drones see and navigate their environment, you might want to check out our guide on the [top drone collision avoidance systems](https://www.jabdrone.com/post/drone-collision-avoidance-top-systems-for-safer-flights), which dives into the sensors that make autonomous flight a reality. The evolution of the brushless motor is a key part of this story, constantly pushing the boundaries of what drones can do.

Common Questions About Drone Brushless Motors

As you get your hands dirty building and flying drones, a lot of practical questions start to pop up. Think of this as your go-to FAQ, where we tackle the most common things pilots and builders wonder about. We'll give you clear, straight-to-the-point answers to help you make smarter choices for your next build.

Can I Use a Higher Voltage Battery with My Motors?

This question comes up all the time, and the honest answer is: it’s complicated. Jumping to a higher voltage battery, say from a 4S to a 6S LiPo, is like dropping a bigger engine into your car. It will dramatically spin up your motor's RPM (since RPM = KV x Voltage), giving you a massive surge of power.

But with great power comes great responsibility—and in this case, a huge spike in current draw and heat.

Before you even think about making that switch, you must check the manufacturer’s thrust data. This is your safety net. It tells you if the motor and your props can handle the extra juice without melting down. If you ignore it, you risk frying the motor's copper windings or even your ESC. A common trick is to swap to smaller or lower-pitch props when you go up in voltage; this helps keep the power draw in a safe range.

What Does the N Rating on Motor Magnets Mean?

You’ve probably seen ratings like N52 on a motor's spec sheet. This "N" rating is all about the strength of the neodymium magnets inside the motor's bell. The number itself is a grade representing the magnet's maximum energy product.

In plain English, a higher number means a stronger magnet. A drone motor rocking powerful N52 or N54 magnets generates a more intense magnetic field, which gives you more torque and better overall efficiency.

So what does that feel like in the air? It means your drone responds instantly to your stick commands. It feels more "locked-in," especially when fighting turbulence like prop wash. This is a game-changer for FPV freestyle pilots and racers who need that crisp, responsive feel.

What Is the Difference Between Inrunner and Outrunner Motors?

The main difference is simple: it’s about which part of the motor actually spins.

For pretty much every multirotor drone out there, the outrunner motor is king. In this design, the outer can—the bell with the magnets glued to it—rotates around the stationary copper windings on the inside (the stator). This setup is brilliant at producing high torque at lower RPMs, which is exactly what you need to spin big propellers directly without needing a heavy gearbox.

An inrunner motor is the exact opposite. The rotor with the magnets is tucked inside and spins within a stationary outer can. Inrunners are screamers—they can hit incredibly high RPMs but don't offer much torque. That's why you see them in things like RC cars or jets where pure speed is the goal. For drones, that raw torque from an outrunner is essential for generating lift and maintaining stability.

Knowing these technical details is vital for building a great quad, but it's just as important to know the rules of the sky. As your setups get more powerful, it’s a smart move to understand the regulations that come with them. You can learn more about the [drone pilot license cost and what you need to know](https://www.jabdrone.com/post/drone-pilot-license-cost-what-you-need-to-know) in our detailed guide.

At JAB Drone, we're committed to providing the expert insights you need to master every aspect of drone technology. Explore our site for more deep dives, reviews, and guides to stay ahead in the world of UAVs. Find your next drone or component at https://www.jabdrone.com.

Comments