Drone Propeller Replacement: Boost Your Drone's Flight

- James Baptiste

- Apr 22, 2025

- 13 min read

Why Perfect Propellers Are Your Drone's Best Friend

Your drone's propellers are absolutely vital for a smooth and controlled flight. They are the only things generating the lift that keeps your drone airborne and stable. This means their condition has a direct impact on flight stability, battery life, and how your drone responds to your commands.

Even a small nick or crack in a propeller can cause vibrations. These vibrations can make your footage shaky and negatively impact your overall flying experience. Worn-out propellers also make your drone's motors work harder, draining the battery much faster. This extra strain can even shorten the lifespan of your battery.

The Impact of Propeller Condition on Flight

Think of your drone's propellers like the tires on your car. Worn-out tires reduce your gas mileage and impact your car’s handling. Similarly, damaged propellers decrease your drone's efficiency and stability. This can lead to unpredictable flight and even crashes.

This is especially important for professional drone pilots. These pilots rely on their equipment for capturing high-quality video and photos, and completing important tasks. Ensuring their propellers are in top condition is essential for success.

The Importance of Timely Drone Propeller Replacement

Replacing your drone's propellers regularly is a smart investment. New propellers restore that sharp, responsive feel, giving you more control and precision in the air. This added control helps you execute maneuvers confidently and capture smoother, more professional-looking footage.

The increasing importance of propellers is reflected in the global drone propellers market. In 2023, the market was valued at approximately US$ 867.4 million. Projections show it reaching over US$ 4,388.2 million by 2033, with a 17.6% CAGR. This impressive growth highlights the rising demand for high-quality propellers for a wide range of drone uses. You can find more detailed statistics here: Factmr

Warning Signs of Propeller Wear

Ignoring signs of wear and tear on your propellers can have serious consequences. It could even lead to mid-air failures and expensive repairs. These signs can be subtle, so it’s important to know what to look for. Being able to spot these often-missed warning signs and taking action can prevent major problems down the line.

Spotting the Telltale Signs Your Propellers Need Replacing

Before every flight, a quick check of your drone's propellers is a smart move. This 60-second pre-flight inspection, a habit of experienced drone pilots, can significantly increase the lifespan of your drone and prevent expensive repairs. It could be the difference between a successful flight and a crash. This section will guide you through the key things to look for when assessing your drone's propellers.

Visual Inspection: A Close-Up Look

Start by carefully examining each propeller for any visible signs of damage.

Cracks: Even the smallest cracks can compromise the structural integrity of the propeller. Never ignore them.

Chips: Chips, particularly near the tips or the base, weaken the propeller and can lead to more serious damage mid-flight.

Deformations: Bent or warped propellers create an imbalance. This affects flight stability, puts extra stress on the motors, and can eventually lead to motor failure.

Pay extra attention to the leading edge of each propeller – the edge that cuts through the air. This area is particularly vulnerable to wear and tear. Even minor damage here can have a big impact on performance. It's similar to a damaged airplane wing; small imperfections can affect lift and stability.

Performance Issues: Listening for Trouble

Beyond visual cues, your drone's performance can also indicate propeller problems. Unexplained vibrations are a major red flag. This new vibration isn't just annoying; it suggests propeller imbalance or damage, leading to increased strain on the motors and reduced battery life.

Decreased flight time is another warning sign. If your flights are shorter than usual, worn-out propellers could be the cause. Damaged propellers force the motors to work harder, draining your battery faster.

The following table summarizes some key warning signs to watch out for:

To help you further assess the condition of your drone propellers, take a look at this checklist:

"Signs Your Drone Propellers Need Replacement" provides a comprehensive checklist of visual and performance indicators that tell you it's time for new propellers.

Warning Sign | Category | Severity Level | Recommended Action |

|---|---|---|---|

Cracks | Visual | High | Replace immediately |

Chips | Visual | Medium-High | Replace soon |

Deformations (bending, warping) | Visual | High | Replace immediately |

Excessive vibration during flight | Performance | Medium-High | Inspect propellers, replace if necessary |

Reduced flight time | Performance | Medium | Inspect propellers, replace if necessary |

Scratches and scuffs | Visual | Low-Medium | Monitor for worsening, consider replacement |

Unusual noises during flight | Performance | Medium | Inspect propellers and related components |

This table provides a quick reference for identifying potential propeller problems. Regularly checking for these signs can prevent more serious issues down the line.

Flight Environment and Habits: Factors Affecting Propeller Life

Your flying environment and style significantly impact propeller lifespan. Sandy beaches, for instance, are tough on propellers due to sand and salt exposure. Dusty or wet conditions also accelerate wear. Aggressive flying, rapid acceleration, and hard landings add stress to your propellers. Being mindful of these factors can help you anticipate when propeller replacement is needed. Learn more in our article about drone maintenance and our other blog posts.

Proactive Maintenance: The Key to Longer Drone Life

By understanding what affects propeller wear and implementing a regular pre-flight inspection, you can greatly reduce the risk of mid-air problems. This proactive approach not only saves you money but also makes your flights safer and more enjoyable. Careful attention to these details is key to maintaining optimal drone performance.

Choosing the Perfect Propellers for Your Flying Style

Finding the right drone propellers isn't a simple task. It's a crucial step in optimizing your drone's performance and achieving your desired flying experience. This involves understanding how seemingly minor specifications can dramatically impact your drone's flight characteristics. Just as different vehicles require specialized tires, your drone needs propellers suited to your specific flying style.

Decoding Propeller Specifications: Diameter and Pitch

Two primary specifications define a propeller's performance: diameter and pitch. Diameter, the measurement across the circle made by the propeller tips, determines the volume of air the propeller moves.

A larger diameter generates more thrust and lift, essential for carrying heavier payloads or achieving faster ascents. However, this added power comes at the cost of increased energy consumption. Pitch, the theoretical distance a propeller moves forward in one rotation, influences the propeller's "bite" into the air.

A higher pitch, analogous to a higher gear on a bicycle, enables higher top speeds but demands more power. Conversely, a lower pitch offers improved acceleration and maneuverability, making it ideal for navigating tight spaces and executing quick turns. Selecting the right diameter and pitch combination for your drone model and intended flying style is crucial.

Drone Propeller Materials: From Plastic to Carbon Fiber

Propeller material significantly impacts performance and durability. Here's a breakdown of common materials:

Plastic: Cost-effective and beginner-friendly, plastic propellers are generally less durable and prone to deformation.

Composite (Nylon, Reinforced Plastic): Offering a balance of durability and performance at a reasonable price, composite propellers are a step up from basic plastic.

Carbon Fiber: The premium choice, carbon fiber propellers are exceptionally strong, lightweight, and stiff, delivering optimal performance and efficiency but at a higher cost.

Understanding the trade-offs among cost, durability, and performance is essential for informed propeller selection. Let's take a closer look at the different materials and their characteristics in the table below.

To help you choose the right propeller material, we've compiled a comparison table:

Drone Propeller Material Comparison Comparison of common propeller materials highlighting their benefits, drawbacks, and ideal use cases

Material | Durability | Weight | Noise Level | Cost | Best For |

|---|---|---|---|---|---|

Plastic | Low | Light | Moderate | Low | Beginners, casual flying |

Composite (Nylon, Reinforced Plastic) | Medium | Medium | Moderate | Medium | General purpose flying, aerial photography |

Carbon Fiber | High | Light | Low | High | Racing, professional applications, high-performance needs |

This table summarizes the key characteristics of each material, helping you make the best choice for your flying needs. Choosing the right material is essential for balancing performance and budget.

Specialized Propeller Types

Beyond standard propellers, specialized options cater to unique requirements:

Silent Propellers: Engineered for noise reduction, these propellers are ideal for flying in noise-sensitive environments.

High-Altitude Propellers: Optimized for thinner air at higher altitudes, these propellers maintain efficiency and performance in challenging conditions.

Folding Propellers: Designed for convenient transport and storage, these propellers fold neatly against the drone when not in use.

These specialized propellers highlight that propeller selection extends beyond simply replacing a broken one; it's about enhancing your overall flying experience. For more information, you can explore Our blog categories.

The drone propeller market is a significant global industry with 441 manufacturers and exporters and 574 importers, resulting in approximately 5,378 shipments. Peru leads as the largest importer, representing about 26% of the global import volume. You can find more detailed statistics at Volza. Ultimately, choosing the perfect propellers involves carefully balancing specifications, materials, and specialized designs to optimize your drone's performance and enhance your flying style.

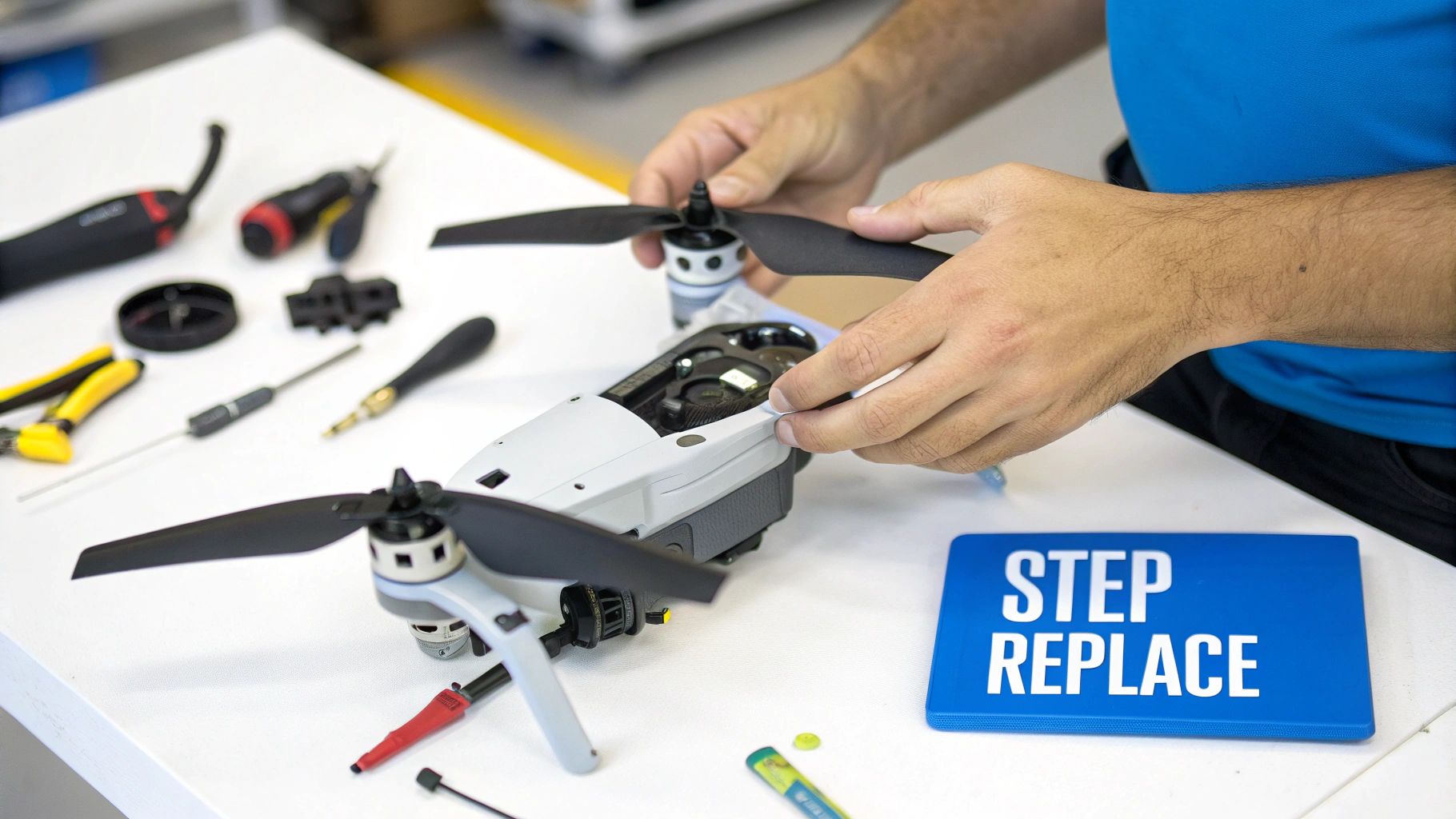

Replacing Propellers Like a Repair Shop Pro

Replacing drone propellers can seem daunting at first. However, with a systematic approach, it's a manageable task. This guide will provide you with the knowledge and skills used by professional drone repair shops, empowering you to confidently replace your drone's propellers. We'll walk you through each step, ensuring a quick and safe return to flight.

Setting Up Your Workspace: Organization is Key

Before starting, establish a clean, organized workspace. This minimizes the chance of losing small components or introducing dust and debris into your drone’s intricate mechanics. Adequate lighting is essential for visibility, especially when dealing with tiny screws. Having the necessary tools within easy reach will also make the process smoother.

Essential Tools: Keep It Simple

While specialized tools are available, most drone propeller replacements require only a few common items. A small screwdriver set with the correct sizes for your drone is vital. Some drones, such as those from DJI, use proprietary screws requiring specific screwdrivers. Consult your drone's manual to verify the appropriate sizes. A small wrench can be helpful for propellers with threaded locks.

A small container or magnetic tray is also recommended for holding screws and other small parts. This simple precaution prevents them from rolling away and getting lost, saving you potential frustration.

Understanding Attachment Systems: Quick-Release vs. Threaded

Drone propellers utilize various attachment mechanisms, with quick-release and threaded being the most common. Quick-release systems prioritize speed and convenience, allowing for swift propeller changes. Threaded propellers, often found on higher-end models, offer a more secure connection.

Removing Damaged Propellers: Avoid Collateral Damage

The key to removing damaged propellers is to avoid further damage to the drone's motors or frame. For quick-release propellers, firmly grip the propeller near the base and follow the detachment instructions specific to your drone model. For threaded propellers, use the appropriate wrench to carefully loosen the locknut before removing the propeller. Avoid excessive force to prevent damage.

Installing New Propellers: Precision Matters

Correct installation is critical for safe and efficient flight. Each propeller is designed for either clockwise or counter-clockwise rotation. It's crucial to match the propeller to the correct motor, usually indicated by markings on the propeller or motor. For threaded propellers, tighten the locknut securely, but avoid overtightening, which can damage components.

Post-Installation Checks: The Repair Shop Secret

After installing new propellers, perform a thorough check before flying. This includes:

Visual Inspection: Carefully examine each propeller for visible damage and ensure they are securely attached.

Spin Test: Gently rotate each propeller by hand, listening for any unusual noises or resistance. This simple test can identify potential issues.

Motor Test: Briefly power on the drone (without taking off) to observe the motors for smooth, consistent rotation. This final check confirms a successful installation.

By following these steps, you can replace your drone propellers just like a professional. This not only saves you money but also provides the confidence of knowing your drone is in optimal flying condition. Mastering these techniques ensures peak performance.

Balancing Your Propellers for Dramatically Better Flights

Even brand-new drone propellers can often benefit from balancing. This often-overlooked step can significantly improve your flying experience, extend the life of your motors, and even give you more flight time per battery charge. This section explains why propeller balancing matters, how it works, and how to do it yourself using various methods.

Why Propeller Balancing Is Crucial

Propeller imbalance, even slight, creates vibrations. Think of a washing machine with an uneven load – it wobbles and vibrates excessively. Similarly, unbalanced drone propellers cause vibrations that ripple through the entire drone. These vibrations reduce efficiency, making your motors work harder and draining your battery faster.

They also put unnecessary stress on the motor bearings, leading to premature wear and tear. Additionally, vibrations negatively impact the quality of your aerial footage, introducing unwanted jello-like wobble. Balancing your propellers is key for a smooth, efficient, and long-lasting flight experience.

Understanding the Science of Balance

Propeller balancing involves ensuring that the weight distribution across each propeller is even. This minimizes vibrations during rotation. A perfectly balanced propeller spins smoothly, like a figure skater in a perfect spin, whereas an unbalanced propeller wobbles, wasting energy and stressing the drone.

This principle applies to all rotating parts in machines, from car tires to helicopter rotors. For drones, the small size and high rotational speeds amplify the effects of even minor imbalances. Even distribution is the core principle behind propeller balancing.

Methods for Balancing Your Drone Propellers

Several methods exist for balancing drone propellers, each offering different levels of precision and cost:

Static Balancing: This method uses a simple propeller balancer, an inexpensive tool readily available online. You mount the propeller on the balancer and identify the heavier blade. Then, you make small adjustments, like adding small pieces of tape to the lighter blade or sanding down the heavier blade, until the propeller rests level in any position. This method, while simple, is surprisingly effective for most hobbyist applications.

Dynamic Balancing: More advanced than static balancing, this method uses vibration analysis apps on your smartphone or computer. These apps analyze the vibration patterns of your drone during flight, pinpointing which propellers are out of balance and by how much. This allows for highly precise adjustments, crucial for professional applications demanding ultimate stability. You might be interested in: our sitemap for more information on this topic and other relevant resources

Field-Expedient Balancing: When a balancer isn't available, this method involves carefully observing the propeller's rotation and making small adjustments based on visual cues. While less precise than the other methods, it can suffice in emergency situations to improve flight stability and reduce vibrations.

Troubleshooting Persistent Vibrations

Sometimes, even after replacing and balancing your propellers, vibrations persist. This can be due to several reasons:

Damaged Motors: A worn-out motor can vibrate excessively, regardless of propeller balance.

Loose Components: Check for any loose screws or parts on the drone frame.

Worn Bearings: Damaged motor bearings create friction and vibration.

Addressing these underlying issues is essential for achieving a smooth and stable flight. By understanding the importance of drone propeller balancing, you can significantly improve your flying experience, extend the life of your equipment, and achieve higher-quality aerial footage.

Extending Propeller Life Through Smart Flying Habits

Extending the lifespan of your drone propellers isn't just about basic upkeep. It's about adopting the proactive habits of experienced pilots. By integrating these strategies, you can significantly reduce how often you need to replace propellers, saving both time and money.

Pre- and Post-Flight Rituals: Small Habits, Big Impact

Just like a pilot checks an airplane before takeoff, pre- and post-flight checks for your drone are crucial for propeller longevity. Before each flight, inspect propellers for any damage, even small cracks or chips. These seemingly minor issues can affect performance and lead to more serious damage during flight. After flying, clean your propellers. Removing dust, dirt, and debris prevents the degradation of the propeller material. These simple checks and cleaning routines only take a few minutes but can prevent hours of repairs and the expense of frequent propeller replacements.

Material-Specific Cleaning: The Right Way to Clean

Cleaning your propellers the right way depends on what they’re made of. For plastic propellers, a damp cloth is usually enough. For carbon fiber propellers, avoid harsh chemicals which can damage the material. Use a carbon fiber cleaner or mild soap and water. This removes buildup without harming the propeller surfaces.

Storage Strategies: Preventing Warping and UV Damage

Proper storage is essential for preventing unseen damage that gradually reduces performance. Store your drone in a cool, dry place, away from direct sunlight. UV exposure weakens propellers over time, especially plastic ones. Consider using propeller guards during storage to prevent bending or warping. This helps maintain propeller shape and integrity, maximizing lifespan and performance.

Smart Flying Techniques: Reducing Stress on Your Propellers

Your flying style has a big impact on propeller wear. Avoid sudden maneuvers, rapid acceleration, and hard landings. These put extra stress on the propellers, leading to faster wear and tear. Smooth, controlled flying not only extends propeller life but also improves your aerial footage and overall flying experience. Think of it like driving – smooth acceleration and braking are better for your tires, just as gentle flying is better for your drone's propellers.

Developing a Strategic Replacement Schedule

Create a replacement schedule based on your flying habits and environment. If you frequently fly in challenging conditions like sandy or dusty areas, you'll need to replace your propellers more often. Aggressive flying also requires more frequent replacements. By understanding these factors, you can create a strategic replacement schedule and avoid being grounded unexpectedly due to worn-out propellers. This ensures you’re always ready to fly with propellers in top condition.

The Future of Drone Propellers You Should Know About

The world of drone propellers is constantly changing, pushing for better efficiency, quieter flights, and longer-lasting designs. Understanding these advancements is key for any drone enthusiast, as they will directly impact how we fly and maintain our drones in the years to come.

Adaptive Pitch Propellers: Mid-Flight Optimization

Imagine drone propellers that can adjust their pitch mid-flight, optimizing for takeoff, cruising, and landing. Adaptive pitch propellers, currently in development, offer just that. This technology could significantly change how drones fly, enabling faster ascents, more efficient cruising, and smoother landings – all in a single flight. For instance, a drone might use a lower pitch for a quick takeoff, then shift to a higher pitch for efficient long-distance travel. This adaptability also means better maneuverability, helping drones navigate tricky environments.

Noise Reduction: Friendlier Skies

Drone noise is a growing concern. Engineers are working on noise-reducing propellers to address this, minimizing sound disturbances. These new designs use innovative blade shapes and materials to dampen noise, making drones significantly quieter. This opens up more possibilities for drone operations, particularly in residential areas and other noise-sensitive locations. Proper maintenance, including a thorough preflight checklist, also helps extend propeller life and minimize noise. Check out this helpful article on preflight checklists for more information.

Revolutionary Materials: Lighter, Stronger, Longer Lasting

The materials used to build drone propellers are also evolving. Carbon-nanotube composites and specialized aerospace alloys offer a remarkable strength-to-weight ratio. This allows for lighter propellers without compromising strength, boosting overall flight performance. These advanced materials also increase durability, meaning propellers last longer and need replacing less often.

Computational Design and Smart Propellers

Computational design techniques are pushing the limits of propeller design. These advanced methods allow for creating propeller shapes impossible to manufacture with traditional techniques. These complex shapes optimize airflow and efficiency, pushing flight performance further. The development of smart propellers with integrated sensors offers real-time performance monitoring and predictive maintenance. These sensors detect changes in vibration and stress, alerting pilots to potential problems before they become serious. This proactive approach to maintenance will improve drone safety and reliability.

The drone propulsion market is projected to grow substantially, from USD 6,694.2 million in 2024 to USD 10,898.2 million by 2029, a CAGR of 10.2%. This growth highlights the increasing demand for innovative propulsion systems, including advanced propellers. You can explore this further at MarketsandMarkets. These developments paint an exciting future for drone technology, with propellers leading the charge. Keeping up with these advancements will allow drone pilots to prepare for quieter, more efficient, and more reliable flights.

Want to learn more about drones? Visit JAB Drone for expert insights, product reviews, and the latest drone news. From beginner guides to professional advice, JAB Drone can help you explore the skies with confidence.

Comments